We provide power for the Al-Andalus, one of the most luxurious touristic trains in Europe

The Al-Andalus has seven Suite-coaches, five of them built in France during the 1920s, with capacity for 74 people and it is 450 metres long, as a 150-storey skyscraper.

Traveling throughout the South of Spain onboard the same coaches used by the British Monarchy in the last century is a luxury available to few. It is the Al-Andalus, one of the most luxurious trains in Europe. We, at Genesal Energy, have designed and delivered a last-generation emergency power system for it.

Comfort, elegance, and spaciousness are the main features of this means of transport from the good times of the Belle Epoque. These days, the amplest train in the world luxury trips around the Spanish rail network offering a service equivalent to a 5-star Hotel.

Why generator sets are essential in trains?

Most of the Spanish national rail network is electrified, trains travel connected to a catenary. However, at certain points in the routes, the power supply is insufficient for the train consumption.

This is why every train must include a generator carriage, that works as a conventional stationary generator set, guaranteeing continuous power supply in case of insufficient power supply or electrical failure.

What did our customer need?

A turnkey project. A comprehensive renovation of the generator carriage.

Accordingly, we installed other ancillary services as medium voltage switchgear and a rectifier. Given that the rail network works with DC power, the train transformers adapt the voltage to feed the different services, from air conditioning to hi-fi, etc.

This is how we did it: ‘In place’, silent and powerful

We undertook the project at Santa Justa Station, in Seville. Home base of the train. Our engineering team travelled South to study the case and take all the needed measurements for the renovation. Later, another team from our HQ in La Coruña, carried out the renovation works and commissioning of the new generator set. Our people are our most valuable asset.

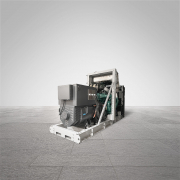

The project meant refurbishing the generator carriage of the train, replacing two obsolete sets from the 1950s which, apart from being very difficult to service, produced very low power and high emissions with a last-generation Stage V 700 kVA set fitted with particle filter, AdBlue injection and medium voltage generation. It was a complete renovation of the structure, from the walls’ soundproofing to the installation of air inlets and outlets. Fitting an exhaust system, a new fuel racking system from an existing fuel tank, switchgear cell and a DC rectifier alongside the complete electrical installation of the carriage.

We are very proud of the successful accomplishment of this project. Once again proving that we are the number 1 manufacturer in Spain when it comes to special projects. Our portfolio of projects and the level of satisfaction of our customers back these words.

Features

- Volvo Stage V engine.

- Automatic fuel racking system from carriage tanks.

- AdBlue tank.

- 2.400v AC medium voltage alternator.

- Medium voltage switchgear cell.

- 3.000v DC rectifier.

- Control integrated in carriage’s system.

- Rockwool soundproofing panels for low noise emissions.

- Roof-integrated air outlets.