Pure reliable energy

Custom

Our firm commitment to R&D+i has positioned us as a benchmark in the international market for customised power generator sets and specialised solutions, developing our own technologies with unique features in the market.

We are certified with UNE 166002:2006 for R&D project management.

We analyse and assess the needs of each client

Customised solutions to energy challenges

Whether it is an auxiliary marine generator, a soundproofed generator set, an emergency generator set designed for low temperatures, anti-seismic equipment, dual frequency or medium voltage capacity, even for cogeneration plants, we are always ready to offer you the most efficient solution.

We study all the characteristics of the installation in detail (environmental conditions, demand, etc.). In this way we can offer you a customised power generation solution with optimal performance and features adapted to your requirements, if necessary, designing customised generator sets for your project from scratch.

We develop the engineering of the entire project, and we not only provide you with a customised generator set that meets your requirements, but we also manage the entire implementation, offering personalised advice on supply and working with your technical team to ensure the success of the implementation.

Pure customised energy

Key phases in the design and manufacture of custom power generators

A customised generator set begins with a paper design to achieve a unique piece that responds to a precise objective. The production process therefore completely differs to that of a standard generator set.

01. Capture of requirements

Each special project needs very specific elements. In this phase, we meet with the client and discuss all the aspects that need to be customised. At the same time, we create a mechanical and electrical pre-design to use as a model. Then we begin the process.

02. Purchase of materials

When the design is almost complete and has been accepted by the client, we make the design freeze. Next, the purchasing department is in charge of arranging the necessary materials to build the generator set.

03. Welding phase

This is the first phase of production. We carry out the cuts and machining that will define the doors, the air and gas outlets, the wiring entrance, etc. In parallel, we weld the chassis that will support the Monoblock, the generator set itself.

04. Painting phase

Paint with protection levels C5I and C5M is key to combatting corrosion and oxidation of the metal parts of the generator set.

05. Partitioning and special soundproofing

In this phase, we divide the container into compartments for the fuel tank, the fire prevention system, the control panel, and all the other elements through a process called “partitioning”. We cover the unit with rock wool panels, an excellent thermal and acoustic insulator.

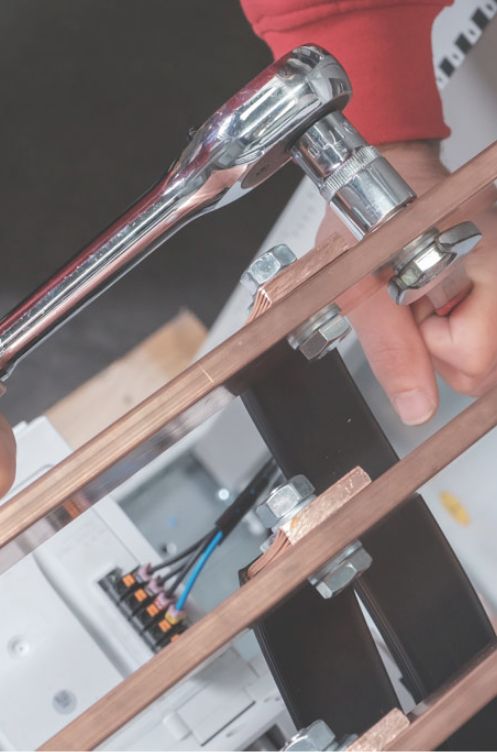

06. Assembly phase

This is the final phase of the production process. We introduce the generator set to the container and install the refrigeration systems, gas outlet, and other components. In addition, we assemble the finishes of the chassis: doors, closures, license plates, stickers and other coverings

07. Testing phase

With the finished product assembled, we perform the tests that guarantee the very high performance standards of our generator sets. We test them all on the load bank at 110% power and we carry out different simulations to see how they respond.

08. Transportation phase

We include transportation in the delivery service.

Pure customised energy

Power ranges for all engines

At Genesal Energy our work is customised to the client, so we have top brand engines in a wide range of powers.

| wdt_ID | Engine | 50 Hz | 60 Hz |

|---|---|---|---|

| 1 | MTU | 450-3300 kVA | 500-3900 kVA |

| 2 | DOOSAN | 200-825 kVA | 230-940 kVA |

| 3 | SCANIA | 250-770 kVA | 275-800 kVA |

| 4 | VOLVO | 85-770 kVA | 85-800 kVA |

| 5 | KOHLER | 5-66 kVA | 6-77 kVA |

| 6 | FPT | 30-617 kVA | 32-687 kVA |

| 7 | CUMMINS | 25-2500 kVA | 25-2500 kVA |

| 8 | PERKINS | 9-2500 kVA | 9-1875 kVA |

| 9 | MITSUBISHI | 800-2650 kVA | 870-2500 kVA |

| 10 | DEUTZ | 13-560 kVA | 15-590 kVA |

| 11 | JOHN DEERE | 30-300 kVA | 32-330 kVA |

Pure reliable energy

Characteristics of customised generator sets

- Generator sets with remote radiator for cooling outside the room.

- Special generator sets for work in extremely cold climates with special internal heating systems.

- Generator sets with seismic certification according to each project.

- Containers compartmentalised into separate rooms.

- Containers with RF100 systems.

- Containers with interior air conditioning systems.

- Cabins/containers painted according to the most demanding requirements and in accordance with ISO 12944.

- Containers with fire extinguishing systems (all types).

- Containers with automatic grilles that prevent the entry of external elements when the generator set is out of operation.

- Dust/sand inlet filtering systems inside the cabins/containers.

- Complete control development to adapt to any type of operation through PLC of any brand, even controlling part of the installation external to the generator set itself.

- Special synchronisation systems between several networks and several generator sets.

- Special protection relays to comply with any protection required according to ANSI regulations.

- Medium voltage generator sets, either by direct generation from the alternator or through a step-up transformer, including medium voltage cells.

- Special tests against cold, heat, rattling, salt spray, rain, etc.