Genesal Energy designs a new set to guarantee supply to supermarkets

Genesal Energy provides innovative solutions adapted to the needs of any sector, including large food & drink companies.

In their premises, maintaining the flow of electricity is crucial to guarantee the good quality of the products and service.

Firstly, the preservation of perishable goods requires constant refrigeration to ensure their safety for consumption and, secondly, the support of the operation of critical systems such as computer systems, lighting systems or security cameras. If a supermarket suffers a power outage, the financial and reputational losses can be considerable, as well as causing serious disruption to customers and employees.

To avoid this type of situation, Genesal Energy’s team of engineers designed a solution for one of these in Getafe, Spain. In addition to guaranteeing the supply, it was also adapted to the needs and measurements of the dedicated space. The energy autonomy of the establishment was secured ensuring that it remains operational in events such as overloads or short-circuits.

Our solution

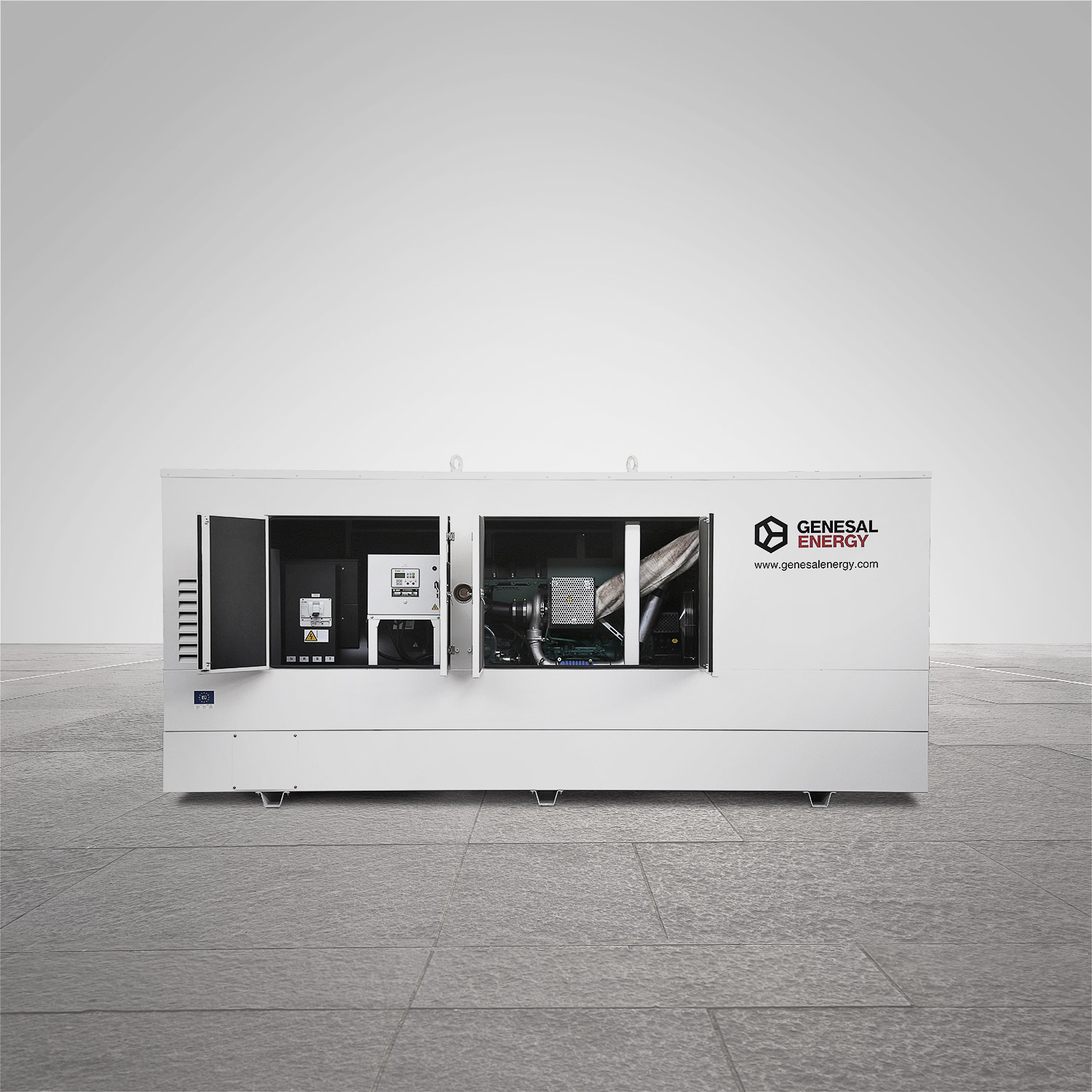

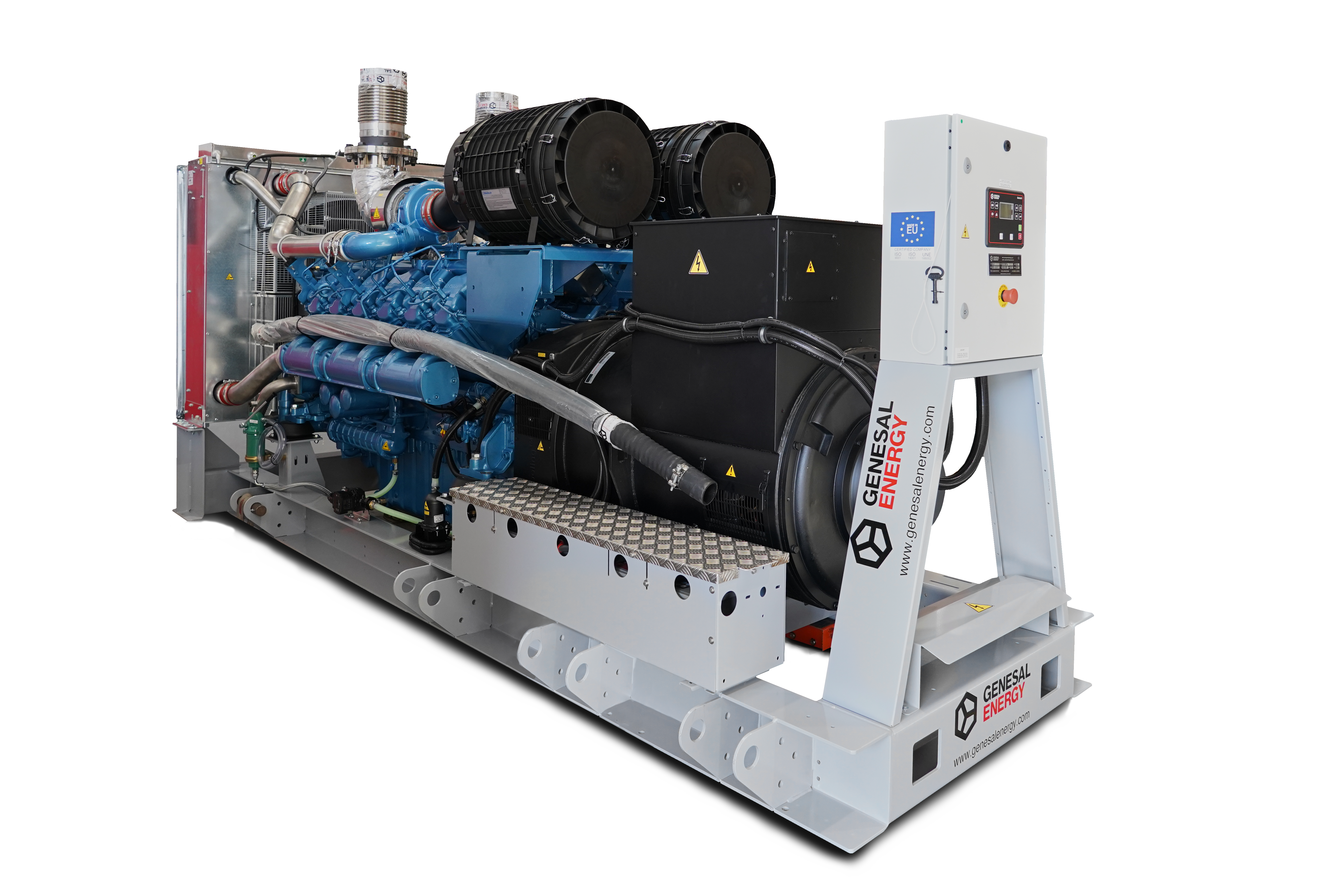

Our engineering department developed a soundproof generator set, with a 450-litre tank and a liquid collection container designed to hold all the fluids that could be leaked (oil, coolant, diesel…).

In addition, a trip coil was fitted in the circuit breaker which acts when there is a power cut, activating the automatic immediately.

Features

- Calculation of necessary cross-sections for air inlet and outlet in the room.

- Circuit breaker with minimum voltage trip coil for possible overload, short circuit or earth fault events.

- Exhaust gas silencer -30dB.

- 1000W preheating system.

- Leak tray for liquid collection.