Designing and supplying efficient energy for a Spanish paradise: The island of Ons

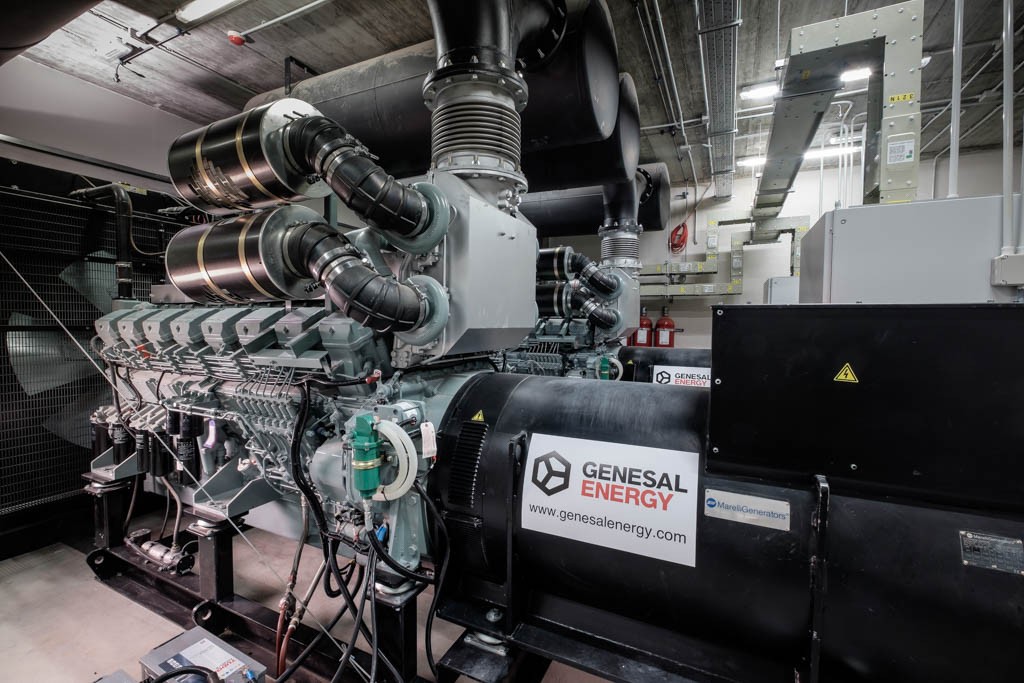

Genesal Energy has designed a diésel generator to supply green energy to the Island of Ons, one of the most beautiful tourist destinations in the region of Galicia in northwest Spain. The Island is a protected reserve within the National Park of the Illas Atlanticas, and due to its situation, it is completely isolated from the mainland power grid.

It was for these reasons that our team of inhouse engineers along with our R&D department created a “different” type of electrical generator, focused on taking great care with the local environment. The tailormade end product entered into operation in the summer of 2017. The generator has been designed to supply energy for the camping site situated on the upper part of the island. The site occupies an area of 8,000sq metres with a capacity for 276 people.

Considered the first self-sustainable camping site in the Galician region, the site already incorporates a system of solar panels to provide electricity. Yet, due to the limited hours of sunshine in this part of the world and the characteristics of the camping site, it has been deemed essential to ensure a round the clock power supply, and for that supply to be sustainable.

The solution designed by Genesal Energy, and in collaboration with Magaral engineering, is made up of a 60-66 Kvas genset in a 2900mm long soundproofed cabin. The genset high attenuating silencer for the exhaust pipe, not to mention many more specifications that make this much more than a conventional electrical generator. In fact, the word unique would be the most appropriate in this case.

The fitted engine for the genset was chosen according to the highest standards possible in relation to quality and established legal norms, ideal for a natural reserve as such is the Island of Ons. The genset supplies electricity, green energy and reduces by up to 50% atmospheric emissions. Also, the extra soundproofing qualities ensure a peaceful coexistence with the campers, especially at night time.

The real difference comes from the specialised system designed and incorporated in to the genset solution, which uses the heat and waste gases generated by the genset to provide sanitary hot water for the camping site kitchens, bathrooms and day to day activity on the campsite. It entails using a thermostatic controlled system to reuse waste gas for heating water. IN this case, unique really means unique.

Having to move the genset to an isolated island off the Galician coast meant overcoming two challenges:

- Logistic: The movement of a 1000 Kilo genset and components, which was executed by boat.

- A protected nature reserve with no mainland power supply: As opposed to an emergency standby power generator it was important to provide a solution that covered needs continuously if necessary and fully respecting the surrounding environment. Mission accomplished!

GENESAL ENERGY designed, manufactured and commissioned eight gensets to provide the hospital with the 11.2 MW needed:

GENESAL ENERGY designed, manufactured and commissioned eight gensets to provide the hospital with the 11.2 MW needed: