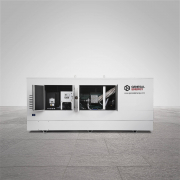

GEN80FC – Extra Soundproof Genset

CHARACTERISTICS

Extra Soundproofed Genset

Power: 80 kVA COP, 100 kVA PRP & 110 kVA STANDBY

Project: Data Processing Centre, Abanca.

Location: Paseo de Recoletos – Madrid

SPECIFICATIONS

- Diésel genset with 65dB(A) sound measurement at 1M distance.

- Integrated silencers on the air intake and the exhaust.

- Double thickness sound absorbing rock wool as standard issue for the entire enclosure including the base.

- Electronic Engine Control Unit installed, which guarantees a more stable performance.

- Alternator provides voltage stability of ±0,5%.

- Card for Modbus set up.

- Sub base fuel tank for a 20 hour plus autonomy at COP rating.

- Integrated fuel level sensors for automatic fuel transfer management.

- Extra addition of silent blocks to add to those mounted between the bench frame and the engine-alternator mono block, in order to eliminate any residual vibrations once installed in the building interior.

CASE STUDY

In the engineering side we had to consider various needs.

On the one hand, and due to the unusual location of the genset inside a building in the middle of Madrid, it was necessary to ensure a genset design solution which met with the local regulations pertaining to legally permitted acoustic levels. Genesal’s engineering department proposed the manufacture of a specially built genset to comply with Madrid’s legally permitted acoustic levels. This involved several key design aspects such as extra thick walls on the genset enclosure, silencers integrated in to the air intake and exhaust systems, as well as sound proofing the base frame. This led to the development of a one piece completely enclosed mono block. Additionally Genesal went a step further and researching the need for added silent block anti-vibration parts to the standard number used in manufacture, to eliminate residual vibrations that may increase the noise output.

This was not the only consideration. Genesal’s engineers correctly assumed that the complexity of the location required a unique fuel transfer and control system for the loads to be handled by the genset. This required a fuel tank to be situated in the basement of the building, and a controlled transfer method to be installed. A special alternator was added to guarantee very high stability at different frequencies regardless of the genset load levels, with an added electronic engine speed control unit (ECU) to ensure continuous stability.