Contact

Do you need a generator set?

Fill in the form with your information if you want one of our generator sets or if you have any questions. We will prepare a quotation for you based on your requirements.

Customer Service Telephone/Fax:

+34 900 730 124Customer service team Email

consultas@genesal.comGENESAL ENERGY

INTERNATIONAL

We operate in over 40 countries worldwide.

EUROPE | AFRICA | LATIN AMERICA | MIDDLE EAST

R&D+i

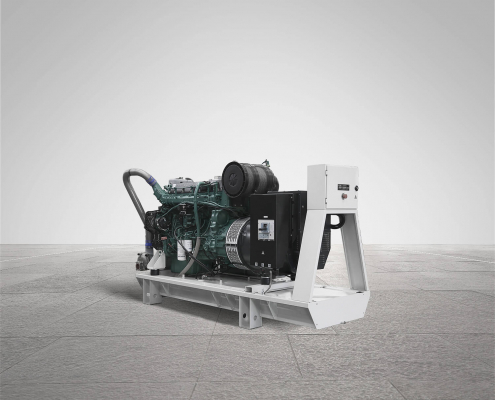

GENERATOR SETS

- Diesel Generator Sets

- Gas Generator Sets

- Hybrid Generator Sets

- Stage V Generator Sets

- REQUEST A QUOTE

CERTIFICATIONS

COMUNICATION

Parroquia de Rois, b28

Polígono Industrial de Bergondo 15165

Bergondo, A Coruña

consultas@genesal.com

Officially registered as Manufacturer with references:

RII_PYA: 7848

RII_ENV: ENV/2023/000004191

RII_AEE: 7087

Members of