In Latin America, as well as in Europe, there are many countries with a growing demand for gensets providing low sound levels (therefore contributing to a greater social well-being), which are also guaranteed to be able to cover power requirements, whether it be for continuous use or in emergency situations.

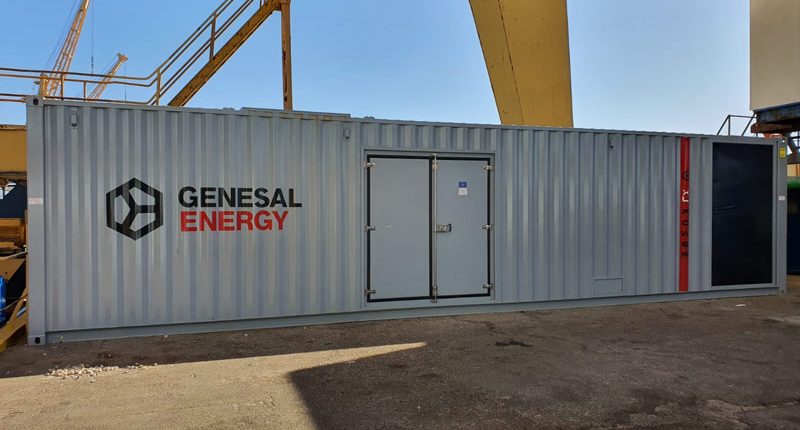

One of these countries is Chile, a market with great possibilities and in constant expansion in the energy sector (especially in the field of renewable energy), for which we’ve designed, manufactured and supplied a total of 18 super-soundproof gensets.

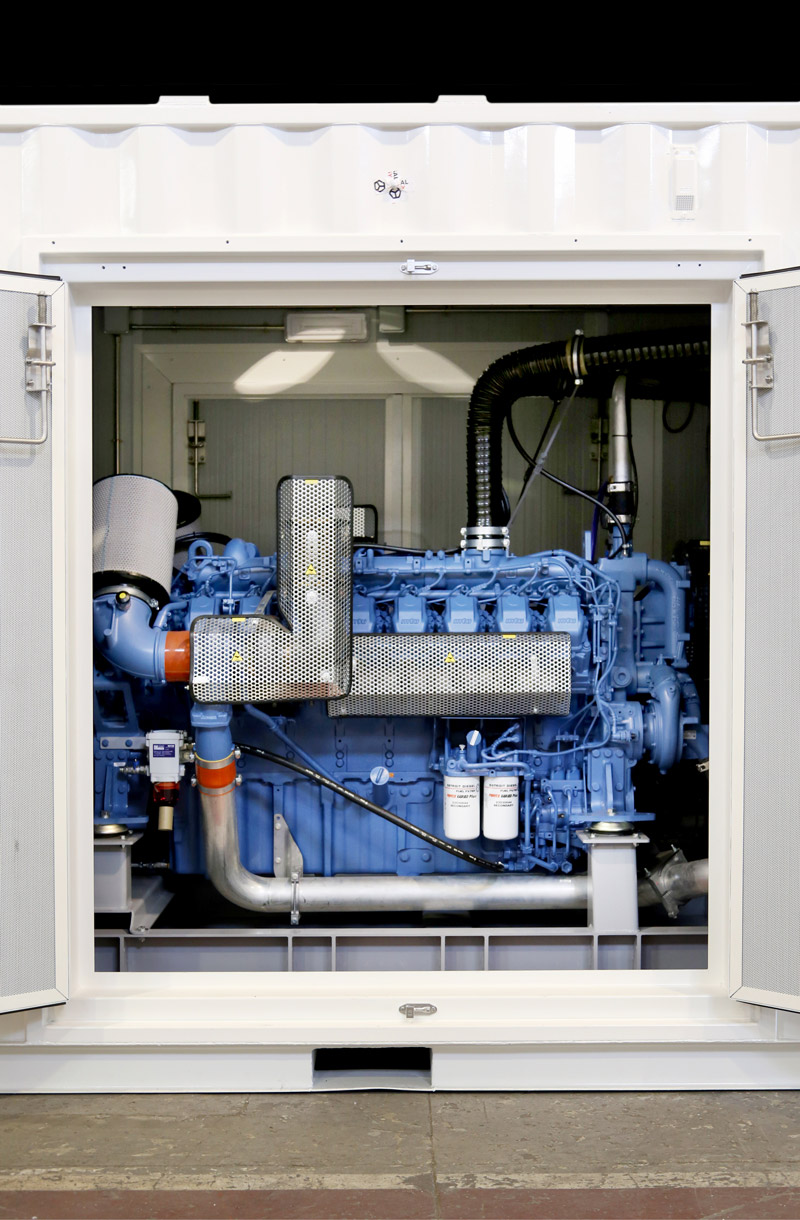

The generator sets were tailor-made according to the client’s needs, and two different models were designed (five gensets of 500/550 kVA and 12 of 1000/1100 kVA), but with a common denominator: their great level of sound attenuation: 65 dB at seven metres distance at the point of maximum emission.

To achieve this, the engineering team and the sales department, which at Genesal Energy always work hand in hand, kept the basic cooling requirements into account, without surpassing the length and width of the 40’HC shipping container which encases the generator sets.

Double-walled fuel tank

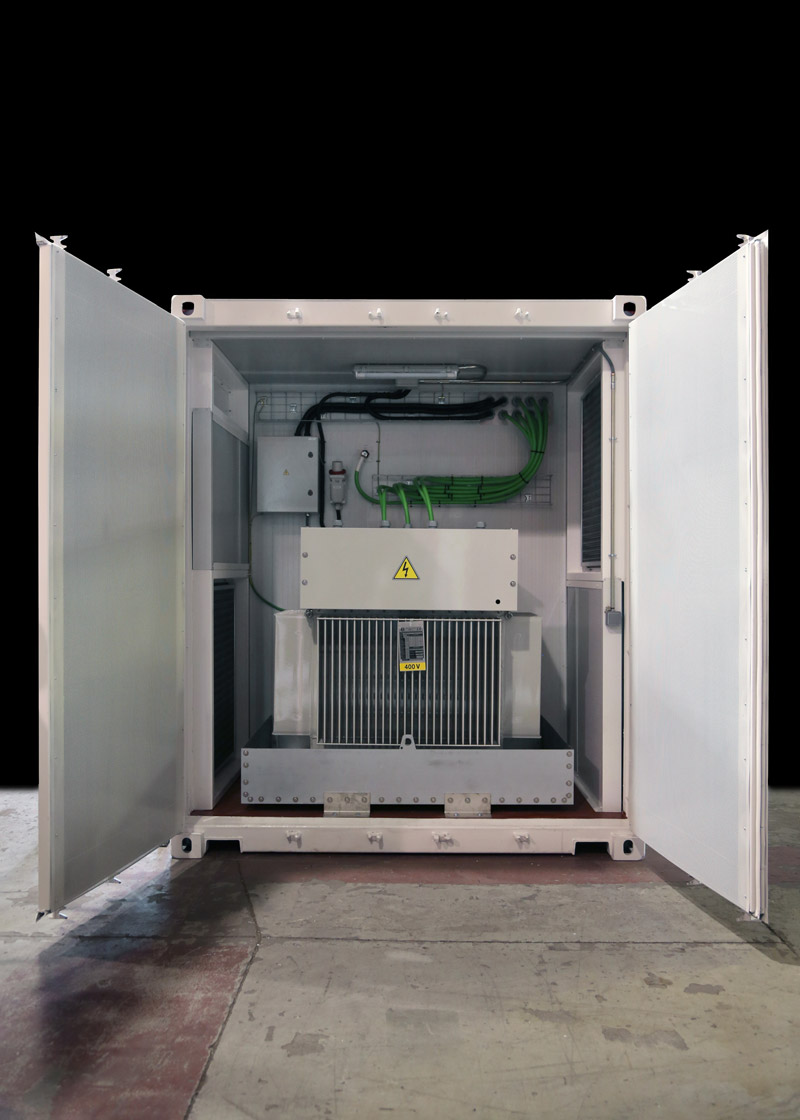

Specifically in the 550kVA unit, we also installed a medium voltage step-up transformer, and in the 1.100 kVA, a 3.000 litre double-walled fuel tank inside the container, as well as control cabinets, silencers, etc.

On the other hand, to achieve a sound level of 65dB it was necessary to decrease the sound levels by 43’5 and 48 dB respectively. To reach this goal, we selected different materials and solutions, some applied in exactly the same way in both models, but others had to be adapted due to the unique characteristics of each unit, which went beyond their engine’s respective power ratings, to be able to comply with the technical specifications requested by the client.

Finally, once the open-field tests of the prototypes had been carried out following the indications and procedure set by the applicable regulations, the results were as follows:

- GEN1100TC: 64.5dB (A) at 7m distance

- GEN550TC: 64.5dB (A) at 7m distance

These are the main features of both models manufactured for Chile by Genesal

| | GEN550TC | GEN1100TC |

|---|

| PRP power | 500 kVA.

| 1000 kVA.

|

| STP power | 500 kVA.

| 1100 kVA.

|

| Voltage | 400/230 V + 23kV transformer.

| 400/230 V

|

| Frequency | 50 Hz. | 50 Hz

|

| RPM | 1.500 | 1.500 |

| Engine brand | MTU | MTU |

| Alternator brand | MECCALTE WITH PMG. | MECCALTE WITH PMG.

|

| Type | Soundproof in 40 HC container.

| Soundproof in 40 HC container. |

| Specific installation rooms | Three independent areas

| Two independent areas

|

| Fuel tank | 1.500 L integrated in the base frame. | 3.000 L double-walled and approved according to Chilean regulations |

| Sound emission level | 56,3dB (A) 7m | 64,5dB (A) 7m.

|

| Paint | ISO 12944 C5M. | ISO 12944 C5M.

|

| Coupling | Elastic between engine-alternator.

| Elastic between engine-alternator. |

| Control system | COMAP (possibility for parallel operation). | DEIF (possibility for parallel operation).

|

| Circuit breaker | Schneider, removable and motorized. | Schneider, removable and motorized. |

| Cooling system | Removable for maintenance.

| Removable for maintenance.

|