Generators are categorized based on their installation and mounting methods. Understanding these categories is essential to select the right generator installation for each project’s specific needs.

Whether it’s mobile generators for remote construction sites, stationary emergency generators inside factories, or outdoor units operating in urban areas, each setup requires specific conditions that define its design and generator mounting type.

Although requirements can vary, three main factors define the installation and arrangement of a generator:

- Mobility – Will the generator remain permanently in one place or move between different locations?

- Environmental Exposure – Will the unit be installed indoors or outdoors?

- Noise Control – Does the location demand minimal noise emissions?

By addressing these questions, you can determine the most suitable generator installation and mounting solution.

Main types of generator installation

Despite the fact that there is an infinity of personalization options, there are 3 types of installations according to the parameters mentioned above.

1. Open stationary installation

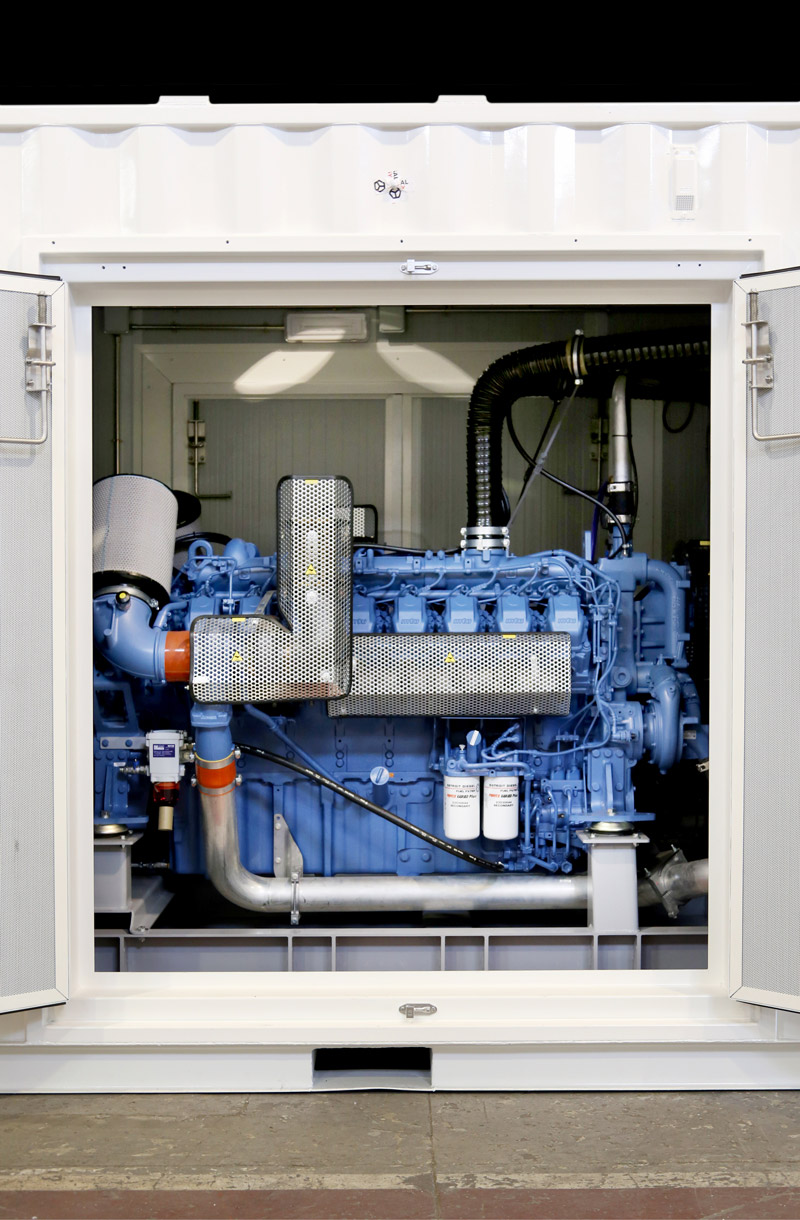

This type of installation is foreseen for projects in which the generator is installed inside a building and it does not need to be moved once installed. Consequently, the generator does not need any casing to protect it from inclement weather, nor does it have any mobility device.

The generator will be installed on a steel bedplate (with or without an integrated fuel tank), capable of sustaining the static mechanical requirements, as well as the vibrations to which the generator will be subjected throughout its service life.

2. Sationary sound-damping installation

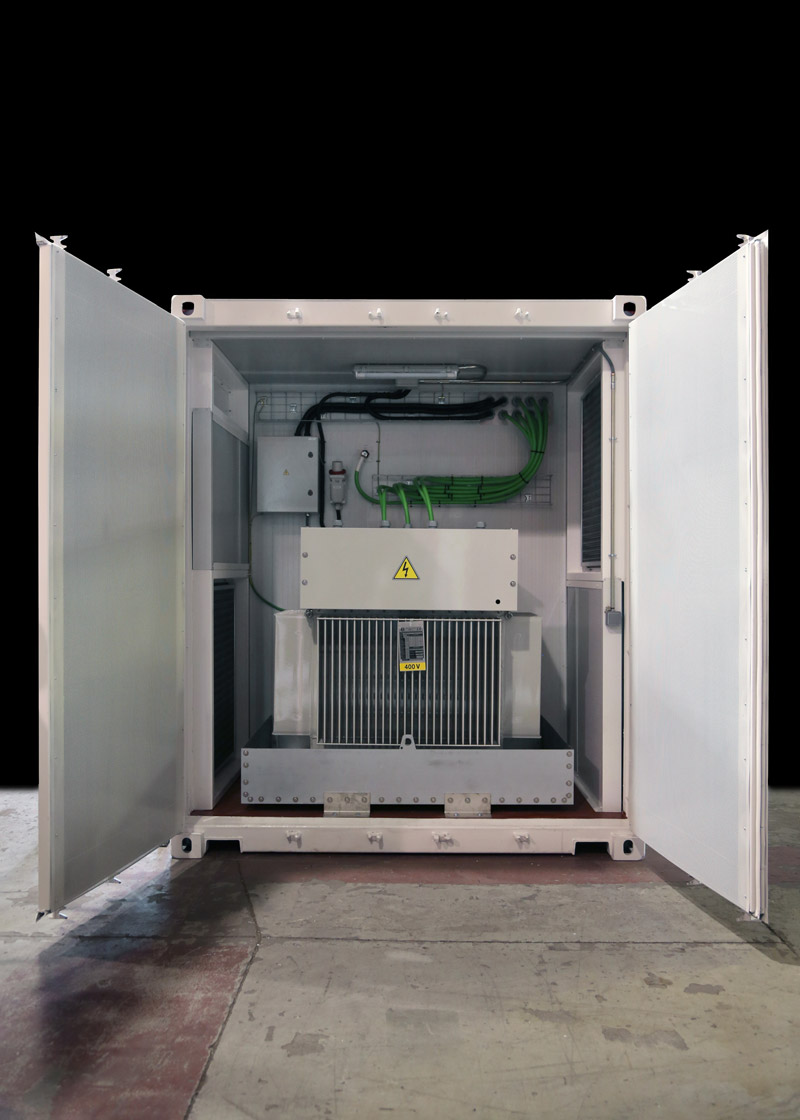

When the generator will be exposed to bad weather conditions, will be stationary and the sound level it produces will have to be low, this type of installation is the ideal one.

The generator is encapsulated in a galvanized steel cabinet, protecting it from inclement weather. The inner part of the hood is covered by sound-damping material, which allows for the reduction of the sound level which is emitted. Therefore, this type of installation is adequate in applications where noise is a crucial factor.

3. Mobile sound-damping installation

This is the type of generator which is usually seen in provisional installations (events, film shootings etc.). Its differentiating feature is that this type of generator must have the possibility to be moved to where energy is required; consequently, it will be installed on a trailer.

The device is placed on some special anti-vibration dampers, capable of sustaining the sheer stress (or lateral deformation) which can happen during circulation: factors such as braking, acceleration or bumps. In this way, one manages to protect the monoblock (the engine-alternator group) and to ensure the generator’s functioning and durability.

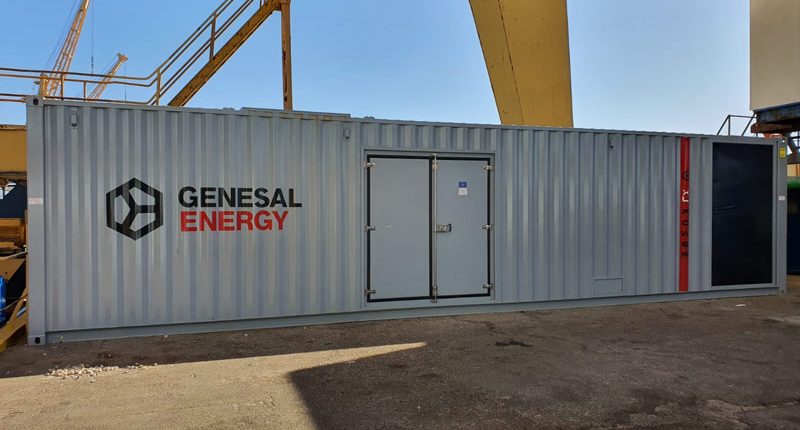

Custom Generator Installation Solutions

At Genesal Energy, we provide generators adapted to these three generic categories of installation and arrangement. They can be further personalized in order to adapt in the best way possible to the specific applications that our customers need.