We bring energy to the “Carlos Tartiere”, the largest football stadium in Asturias with a seating capacity of 30,500

With 30,500 seating capacity, the “Carlos Tartiere” municipal football stadium, home to Real Oviedo, is also the largest sports venue in Asturias.

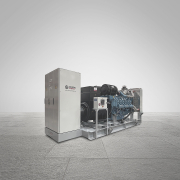

Genesal Energy has designed an open and customised generator set for stadium to guarantee the electricity supply in the event of a possible failure of the main grid. If it happens, the show must go on.

For facilities of this type, the availability of emergency generators has become compulsory by law. The reason is to prevent a simple blackout from forcing the cancellation of a match or competition, with the consequent inconvenience that this would cause the players, spectators and, above all, the club, as it would have serious economic and reputational consequences.

Emergency generator for stadium

“The installation of a generator set in a football stadium guarantees 100% of the electricity supply and that the events in the stadium can take place normally, without problems”, explained the Genesal Energy Engineering Department.

In this type of project, the generator sets must have highly reliable engines to assume the loads quickly in the event of a grid failure, maintaining not only the frequency but also the generation voltage.

Genesal Energy is perfectly aware of the importance of small details and precision in the manufacturing process of generating sets for sports venues and we have carried out numerous projects in this sector. Among our latest works we can highlight the emergency systems for the Mendizorroza stadium and for the municipal stadium of Anduva.

Which was our solution for Real Oviedo FC?

Our client needed to replace a generator in poor condition and reorientate the air inlet and gas outlet due to works being carried out at the sports facility. Based on this premise, the engineering department developed an open generator on a laminated ‘U’ with an independent 1,000 litre tank, switch on alternator and compact box of two batteries. The customer required the input to the group power with two cables per phase and the customised manufacture of the hopper and bellow for the air outlet of the radiator.

Features

- Emergency unit with external start-up.

- Open skid on laminated ‘U’.

- 4-pole CB on alternator.

- Dimensions adapted to customer’s room.

- ComAp InteliLite4 AMF 25 controller.

- Additional heating pump.

- Additional tank 1,000 litres.