We participated in the construction of Cuyoaco, the great solar power plant which will power 163.000 homes in Mexico

Genesal Energy participated in the construction of Cuyoaco’s first solar park, located in the Mexican state of Puebla and built on a surface of 755 hectares between the municipalities of Cuyoaco and Ocotepec.

The future 200MW photovoltaic power plant will become a reality thanks to the Mexican Government’s 235 million dollar investment, which will allow this region to have access to 730.000 panels to provide cutting-edge renewable energy, offering clean and renewable electricity.

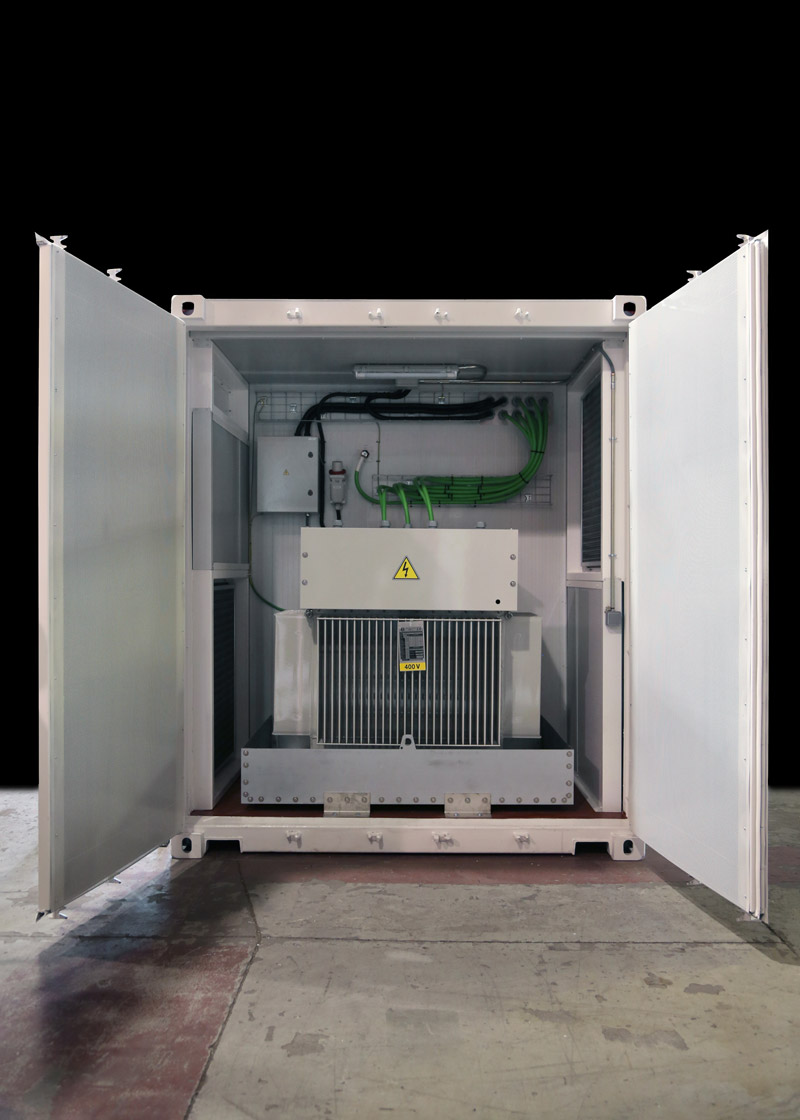

With a total of two substations, one booster and one switching, the construction of the plant has had a great economic impact on the area through the creation of 1.000 jobs.

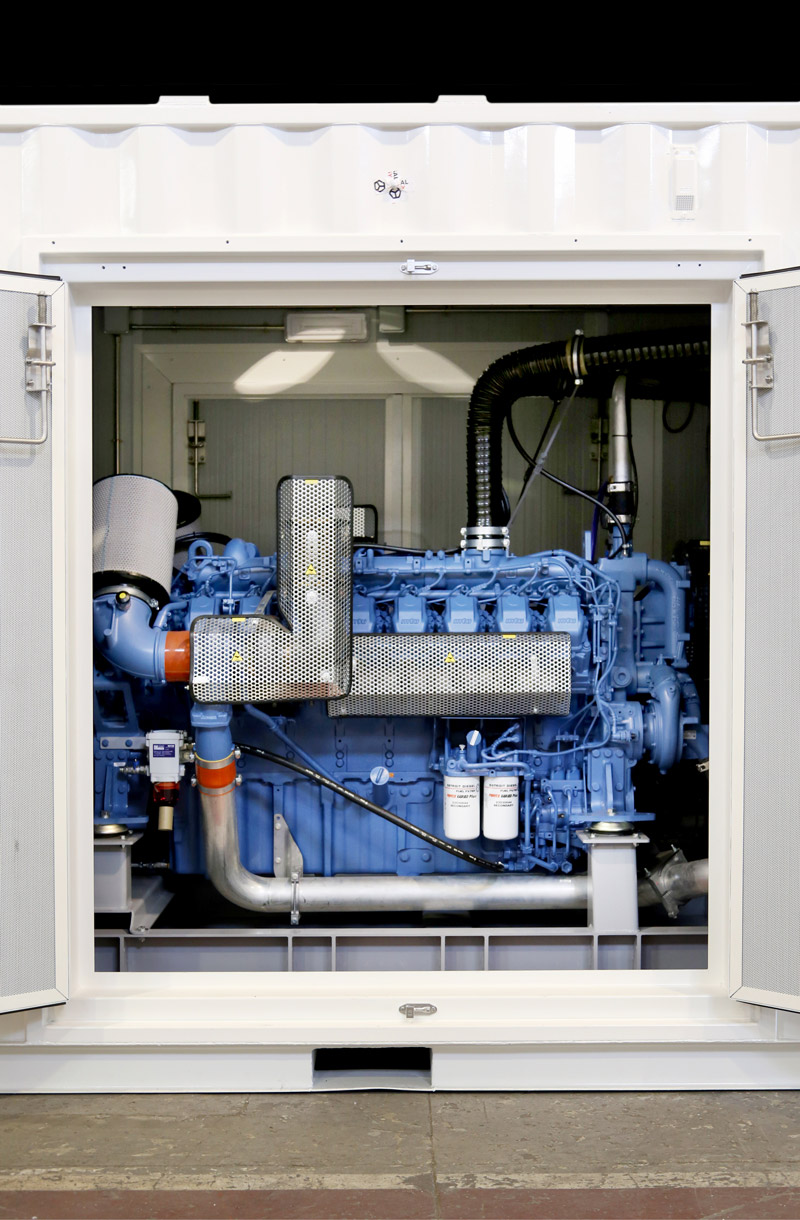

Genesal Energy will provide all of its experience in the renewable energy sector to this important project, through the design, manufacture and supply of a 395 kVA emergency genset for one of the substations. Specifically, the generator set will support the solar power plant’s booster substation.

Commitment with the environment

Genesal Energy’s focus on renewable energy is evergrowing, both nationally and internationally, and this is because of its great advantages and benefits in the industry as well as the company’s commitment with the environment.

In this case, the Cuyoaco photovoltaic plant isn’t only the first in the region to offer this type of technology, but it will prevent the emission of more than 145.000 tons of CO2 to the atmosphere, and will generate 551 GWh every year, the equivalent of supplying power to 163.000 Mexican homes.

Features

- 360-395 kVA soundproof generator set with FPT engine and Mecc Alte alternator (60Hz, 1800rpm, 220/127V).

- Prepared to operate upon mains failure (automatic start).

- Genset painted in the colour required by the client (RAL 1021).

- Monoblock painted in the colour required by the client.

- Alternator anti-condensation heating.

- Control panel anti-condensation heating.

- IB-Lite module for Modbus TCP/IP communication.

- 1050 L bunded tank.

- Analogic voltmeter and ammeter.