Genesal Energy takes part in the undersea Greenlink highway project that will bring green energy to Great Britain and Ireland

Greenlink: A huge HVDC interconnector will link Ireland and Great Britain to bring electricity to 350,000 homes.

Greenlink, the colossal engineering project designed to bring clean energy to thousands of people.

The Greenlink HVDC interconnector is an immense undersea highway which features are as spectacular as its construction. The interconnector will have a capacity of 500 MW and a length of 160 kilometres, the distance separating the counties of Wexford in Ireland and Pembrokeshire in Wales. Its entry into service, scheduled for this year, will enable the supply of clean electricity pursuing the aim of achieving zero emissions. This project has been declared a Project of Common Interest by the EU).

Our involvement in the project

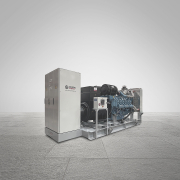

For this mega project, delivered by Siemens Energy and Sumitomo Electric, Genesal Energy designed three generator sets to provide emergency power at both ends of the giant interconnector. Three special units developed at our HQ in Northern Spain to guarantee the supply of the two vital facilities in the connection of the electricity grid of Great Britain and Ireland.

“If for any reason there were to be a lack of supply, it would cause a major grid failure”, explains our engineering team, highlighting the importance of having precise, robust and extremely reliable contingency gensets.

Making a difference

For the Greenlink project, our client Siemens Energy requested the generators to be fully operated, controlled and monitored from the genset control panel. The solution we provided consisted of bespoke generators including the following features:

- Bespoke soundproofing.

- Great Britain and Ireland Regulations compliant in terms of air conditioning, motorised grilles or liquid retention systems. These latter trays fitted with sensors monitored from the control panel.

- Integrated into the container Load-Banks so that the generator sets are always in the optimum working load range.

Smart Grids

The Greenlink subsea interconnector project is perfectly in line with our policy of putting innovation at the service of sustainability and the environment. It is also a clear example of a Smart grid or intelligent electrical network that has been conceived to facilitate the transport and distribution of green energy.

2xGEN1100YC Features

- Power output panel integrated in the same soundproofed container as the genset.

- Engine coolant recirculation and heating system to provide the right temperature when starting the unit.

- Air conditioning system in the genset control room.

- Motorised louvers.

- Liquids collection tray.

- Integrated load bank.

- Surface treatment of the container according to ISO 12944 standard, in C5I finish.

GEN175YI Features

- 160/175 kVA soundproofed unit. 730 L tank (17 hours autonomy at 100% load) and liquid collection tray integrated in the canopy.

- Canopy adapted to the customer’s room.

- Reduced dimensions due to space limitations.

- Canopy designed to be attached to the wall. The doors on the side were sized to open accordingly.

- -30 dB(A) Exhaust gas silencer.

- 80 kW Resistor Load Bank, with 4 automatic steps of 20 kW each, integrated in the Canopy.

- Interior Space Lighting.

- C5M Surface treatment in accordance with the ISO12944 standard.