Sustainability is entering a new phase. After years of directives, reports, and standards, Europe has realised that reporting alone is not enough — what matters is not how much is reported, but how much is transformed. With the approval of the Omnibus Regulation, the European Commission is taking a decisive step in that direction, simplifying the way companies report their environmental, social, and governance performance so that sustainability regains the meaning it should never have lost: action.

Properly managed sustainability not only reduces costs or emissions — it also opens doors.

This regulation was not created to lower ambition, but to restore coherence. In recent years, the CSRD Directive and the European Sustainability Reporting Standards (ESRS) have raised the bar for corporate reporting, but in doing so, they also imposed a disproportionate burden on many SMEs. It’s not just about gathering information: the CSRD required companies to measure dozens of environmental, social, and governance indicators with the same level of detail as large corporations. For an industrial SME, that means allocating human and financial resources it may not have, creating complex management systems, investing in digital tracking tools, and training staff in methodologies that until recently were exclusive to multinational ESG departments. In practice, sustainability was starting to look more like an exercise in bureaucracy than a process of improvement, diverting attention from the real goal: reducing impacts and creating value.

The Omnibus Regulation, approved in 2025, aims to correct that course. Its goal is to simplify administrative burdens and focus on material indicators — those that truly reflect an organisation’s impact on its surroundings. It’s essentially the same approach that guides our evolution: data that inspire decisions, measurements that drive change, sustainability that translates into action.

Measuring What Matters — and Acting on What Can Be Measured

At Genesal Energy, we’ve always understood sustainability as a tool for innovation and improvement, not a reporting obligation. That’s why, even before the Omnibus Regulation came into force, we were already working under the principles it now promotes: prioritising what’s relevant, reducing complexity, and focusing management on tangible results.

The new European framework particularly strengthens three key areas — those that concentrate most of the changes introduced by the Omnibus Regulation:

- E1: Climate change. Updated requirements for measuring greenhouse gas emissions, improving energy efficiency, and advancing towards a genuine transition to clean energy.

- E5: Resources and circularity. Simplified indicators with greater emphasis on responsible use of materials, waste reduction, and the adoption of circular economy principles.

- S1: People and the value chain. Strengthened social aspects: training, occupational health and safety, and ethical management across the entire supply chain.

E1. Climate Change: More Efficient Energy, Lower Impact

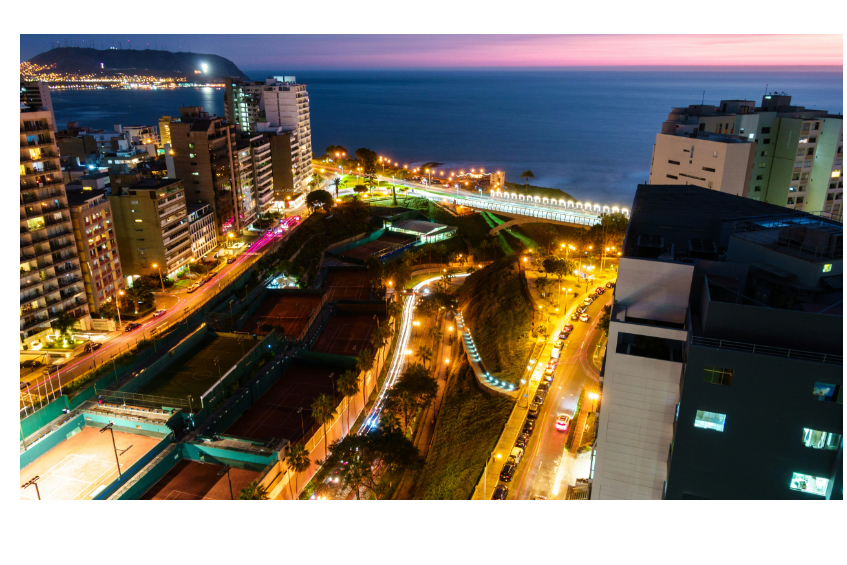

Our commitment to climate action is reflected in the way we manage energy. At our facilities in Bergondo (A Coruña), we have developed a model that integrates renewable sources, smart storage, and consumption optimisation.

The photovoltaic façades and roofs of our B27 and B28 plants generate part of the electricity we consume. Thanks to OGGY, our energy management and storage system, we can monitor production, consumption, and energy flow in real time. Its algorithm automatically decides whether to self-consume, store, or feed energy back into the grid — optimising every kilowatt used.

The results are tangible:

- We have reduced our annual energy consumption by 27%.

- We have improved the energy efficiency rating of our facilities from Category E to B.

- We avoid more than 23 tonnes of CO₂ emissions per year.

These figures are more than indicators — they are proof that sustainability is also a matter of engineering. Our industrial complex now operates as a small microgrid: an energy ecosystem capable of producing, storing, and managing its own electricity efficiently and autonomously.

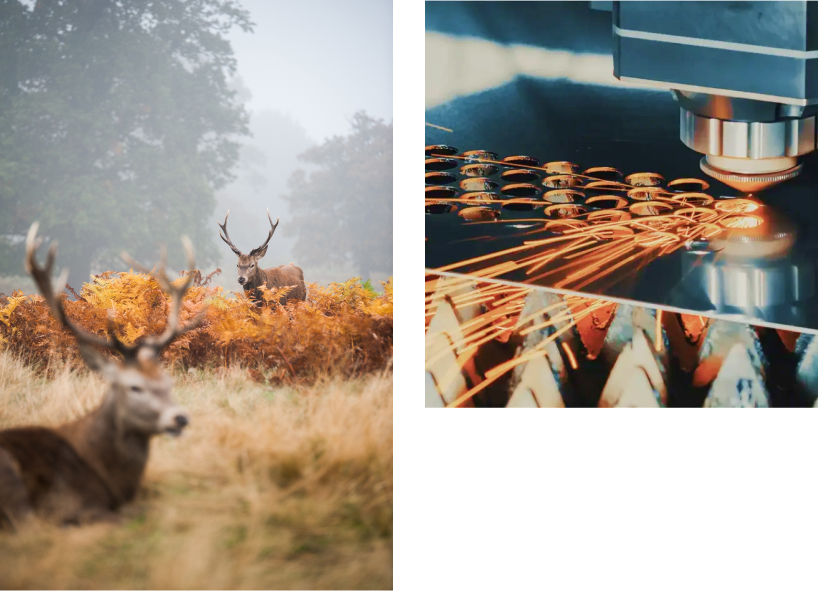

E5. Resources and Circularity: Designing for the Entire Lifecycle

In this new European context, responsible resource management has become more relevant than ever — and at Genesal Energy, we have long been working in that direction. Efficient use of materials, waste reduction, and the incorporation of circular economy criteria are at the core of our eco-design policy.

That’s why we implemented an eco-design management system certified under ISO 14006, which enables us to assess the impact of each component, material, or manufacturing process — and redesign wherever there’s room for improvement.

Simplify administrative burdens and focus on material indicators — those that truly reflect an organisation’s impact on its surroundings.

This work has led to concrete progress:

- Replacement of conventional materials with recycled or recyclable ones — for example, replacing metal parts with 3D-printed recycled polymers, reducing emissions linked to transport and processing.

- Incorporation of local suppliers (km 0) to cut the logistics footprint.

- Elimination of welding or painting processes in certain components, reducing emissions and waste.

Thanks to these actions, some components have reduced their carbon footprint by more than 80% compared to the original materials.

But eco-design goes beyond the technical aspect — it also transforms the way we communicate. Our eco-designed products include environmental data and comparisons that allow clients to understand the savings in emissions and materials compared to previous models. This transparency is part of our commitment: providing clear, useful, and verifiable data that reflect the positive impact of every improvement we make.

S1. People and Knowledge: Learning to Transform

Sustainability is not limited to technology or processes; it also has a human dimension that is essential for progress. At Genesal Energy, we understand that knowledge, education, and social collaboration are fundamental pillars for building a fair and lasting energy transition — and we channel that commitment through the Genesal Energy Foundation.

Through the Foundation, we promote educational, social, and environmental projects that reflect our understanding of sustainability as a shared effort between business and society. We carry out training and awareness activities on energy and environmental issues, support cultural and social initiatives in our local community, and collaborate with organisations working towards more balanced and sustainable development.

Efficient use of materials, waste reduction, and the incorporation of circular economy criteria are at the core of our eco-design policy.

Our goal is to create a positive impact that goes beyond industrial activity — contributing to people’s well-being and to the progress of the environment in which we operate. We believe sustainability begins in the factory, but only becomes meaningful when it’s shared — when knowledge, responsibility, and social action move forward together.

From Measurement to Action

Measurement only makes sense if it leads to action — and at Genesal Energy, we’ve been living by that principle for years. Our environmental policy and management systems — certified under ISO 14001, ISO 14006, ISO 45001, ISO 9001, and UNE 166002 — enable us to turn indicators into technical and business decisions.

We measure our emissions, consumption, and waste — but what matters most is what we do with that information: we select sustainable suppliers, redesign parts, optimise packaging, improve testing efficiency, and reduce impacts at every production stage. In our experience, industrial sustainability is managed with the same precision as any engineering process. It’s not a separate part of the business — it’s part of the way we design, manufacture, and operate.

The new European framework reinforces this vision. Properly managed sustainability not only reduces costs or emissions — it also opens doors. It allows us to access green financing, participate in European projects, and be chosen by clients who value vision and environmental commitment. Sustainability is no longer an obligation; it’s a credential — and a guarantee: the mark of a company that innovates, adapts, and embraces its role in the energy transition with coherence and responsibility.

That’s why we continue to work by a simple principle: less bureaucracy, more innovation; fewer papers, more clean energy; less noise, more consistency.

Europe’s energy transition will be built on data — but above all, on examples. And ours is that of an industrial SME that has decided to integrate sustainability into its DNA — not as a distant goal, but as a way of moving forward every day.