Generator installation and mounting

/in Articles, Communication/by genesalGenerators are categorized based on their installation and mounting methods. Understanding these categories is essential to select the right generator installation for each project’s specific needs.

Whether it’s mobile generators for remote construction sites, stationary emergency generators inside factories, or outdoor units operating in urban areas, each setup requires specific conditions that define its design and generator mounting type.

Although requirements can vary, three main factors define the installation and arrangement of a generator:

- Mobility – Will the generator remain permanently in one place or move between different locations?

- Environmental Exposure – Will the unit be installed indoors or outdoors?

- Noise Control – Does the location demand minimal noise emissions?

By addressing these questions, you can determine the most suitable generator installation and mounting solution.

Main types of generator installation

Despite the fact that there is an infinity of personalization options, there are 3 types of installations according to the parameters mentioned above.

1. Open stationary installation

This type of installation is foreseen for projects in which the generator is installed inside a building and it does not need to be moved once installed. Consequently, the generator does not need any casing to protect it from inclement weather, nor does it have any mobility device.

The generator will be installed on a steel bedplate (with or without an integrated fuel tank), capable of sustaining the static mechanical requirements, as well as the vibrations to which the generator will be subjected throughout its service life.

2. Sationary sound-damping installation

When the generator will be exposed to bad weather conditions, will be stationary and the sound level it produces will have to be low, this type of installation is the ideal one.

The generator is encapsulated in a galvanized steel cabinet, protecting it from inclement weather. The inner part of the hood is covered by sound-damping material, which allows for the reduction of the sound level which is emitted. Therefore, this type of installation is adequate in applications where noise is a crucial factor.

3. Mobile sound-damping installation

This is the type of generator which is usually seen in provisional installations (events, film shootings etc.). Its differentiating feature is that this type of generator must have the possibility to be moved to where energy is required; consequently, it will be installed on a trailer.

The device is placed on some special anti-vibration dampers, capable of sustaining the sheer stress (or lateral deformation) which can happen during circulation: factors such as braking, acceleration or bumps. In this way, one manages to protect the monoblock (the engine-alternator group) and to ensure the generator’s functioning and durability.

Custom Generator Installation Solutions

At Genesal Energy, we provide generators adapted to these three generic categories of installation and arrangement. They can be further personalized in order to adapt in the best way possible to the specific applications that our customers need.

Speed regulation on generators: power without ups and downs

/in Articles, Communication/by GestorWhat we demand of a generator is a stable power delivery. And a constant engine speed is crucial in achieving this.

A speed generator set must maintain a consistent engine speed, as this directly affects power frequency and overall performance.

The famous Swiss architect Le Corbusier said that machines are “a fantastic perfection tool”. However, experience tells us that even the most sophisticated machinery is not perfect. Although the mechanical systems are designed to be balanced and deliver based on optimal parameters, one must take into account that there are always some factors which can alter their efficiency.

The speed of an engine, for example, may be affected by a drop in voltage or by power surges. And, in the case of generators, such variations are of critical importance, given that the engine speed directly determines its operating frequency.

Logically, this can entail a problem, because the thing that interests us about a generator is that it be capable of maintaining the most stable power possible around a certain value.

The good news? Everything is foreseen and technology provides us with the solutions for the engines never to lose direction.

Generator speed control systems: ensuring reliable power output

At present, the engines powering electrical generators contain a speed regulator for speed control.

The function of this regulator is to detect any imbalance in the engine speed and to cause it to revert quickly to its optimal working regime.

Thanks to this device, our generator’s engine will always keep a constant rhythm. In this way, the generator will be capable of always complying with the requirements of the load, giving us the power that we need to obtain.

Moreover, the speed regulator acts as a security device, because it protects the engine from excessive speeds which can cause the engine to break down.

What controls engine speed in engines that power generators?

Engine speed in generators is controlled by a speed governor, also known as a generator speed controller. This device monitors the engine’s RPM and adjusts the fuel supply to maintain a stable speed under varying load conditions. In modern generator sets, this can be mechanical, electronic, or a combination of both systems.

Genesal Energy: reliable engines

At GENESAL ENERGY, we offer you diesel generators equipped with three different types of governed engines:

- Engines with mechanical controls

- Engines with mechanical controls and inbuilt electronic controls

- Electronic engines

All of these are designed to recuperate the working frequency, both after a load impact and after a sudden drop thereof.

The response to the drop in frequency will depend on:

- The inertia of the engine itself.

- The inertia of the alternator.

- The characteristics allowed by the installed AVR (Automatic Voltage Regulator).

At the same time, in the engines with mechanical speed regulation, we apply a parameter called “speed drop” or “droop”. This parameter represents the percentage of over-speeding that the engine is experiencing when it is operating without a load, compared to the nominal speed (at full load). Once we have calculated this, we can configure the engine so that it quickly stabilizes when a load is applied to it.

All regulators need a certain period of time in order to act. At GENESAL ENERGY, we carry out all the necessary adjustments and tests to ensure that the regulators control the engine speed and the generator frequency correctly. In this way, we give a reliable response to our clients’ requirements.

DISCOVER MORE OF GENESAL ENERGY’S PROJECTS

How do variables affect Generator Sizing?

/in Articles, Communication/by genesal

Analyzing the effect of voltage and frequency drops is indispensable for deciding which engines and alternators are more adequate for a generator.

Voltages are not a static phenomenon. They fluctuate resulting in peaks and drops during certain phases of the equipment’s functioning.

In fact, when we speak about circuits we distinguish between two types of situations:

- The steady condition: It is the stationary situation of normal functioning in which the voltage ows in a balanced state according to the conditions determined by the network.

- The transitional state: it occurs in certain periods of time in which the voltages and electrical intensities vary, before the circuit comes to its steady state and becomes stabilized.

The voltage variations occurring during these transitional periods are known as variables.

When do variables occur?

Logically, the normal situation in which variables occur is when we cause a circuit to pass from one condition to another, i.e. at the moment of connecting or disconnecting the equipment.

In fact, when we switch on and off a generator, short voltage peaks are triggered. Although they tend to end by themselves, we must not take them easily. Why is that? Because if the alternator and the engine happen not to be capable of coping with them, major functioning problems may ensue in the generator.

A matter of analysis

For this reason, in the process of designing and sizing a generator, it is indispensable to carry out a strict variable analysis.

Do you want to know the keys to be able to do this analysis?

At Genesal Energy we advise our clients and offer them the solution which best adapts to their project.

Discover how to configure your generator set

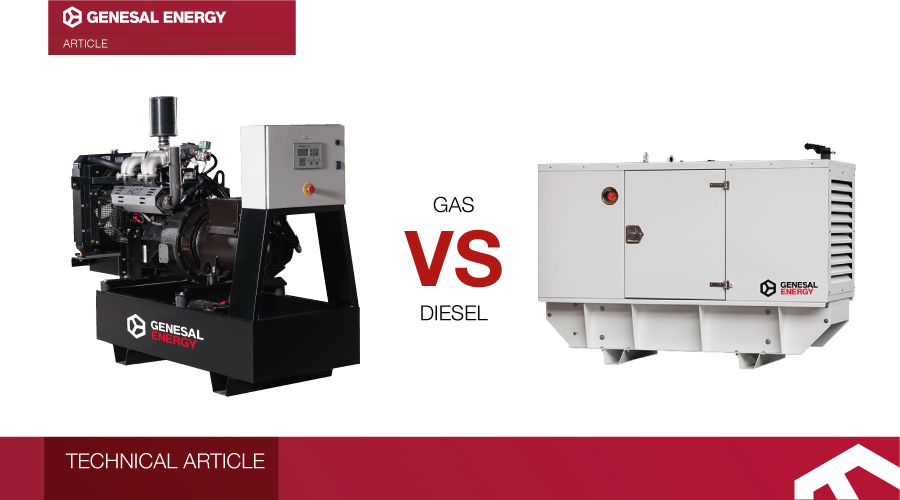

Diesel vs. Natural Gas Generators: Key Differences and Use Cases

/in Articles, Communication/by genesal

The two most common generator types on the market are diesel engine powered generators and those using gas powered engines.

Apart from the fuel powering them, they have other distinctive qualities which make them more or less adequate according to the use we want to give them.

Let’s see what they are.

Note: In this article, “gas” refers to natural gas or liquefied petroleum gas (LPG), not gasoline (petrol). These are commonly used in gas-powered generators, not to be confused with petrol-fueled engines.

Diesel generators

The reliability of a classic

For quite a long time, diesel engine generators have been a standard in the market. Their good reputation was the result of a great flexibility of application, both in industrial and household areas, as well as their robustness and reliability.

This type of generator may be used as a main power supply, as well as for co-generation or emergency applications. They are fully autonomous and may, therefore, function in places which have absolutely no power-supplying networks.

What advantages have made diesel generators so popular?

- They are more easily disassembled and installed than gas units, making their installation wherever needed a simpler task, while also using a fuel which is easily accessible and more economical than gasoline.

- They are robust and sustainable, capable of ensuring many hours of yearly operation.

- Diesel fuel gives high efficiency to the equipment using it because it burns at a much higher temperature than gasoline.

- Diesel fuel is also very safe because it is less flammable than other types of fuel.

The main disadvantage of this type of generator, as in the case of any machinery which includes a diesel engine, is that it causes high levels of polluting gas emissions. Therefore, the present day diesel generators incorporate an additional antiparticle filtration system that ensures its conformity with the legislation in force.

Natural gas powered generators

Clean and economical energy

Gas engine generators have gained much popularity due to their great reliability, cost efficiency and sustainability.

This type of generator can be used as a primary power source, in co-generation applications or as an emergency source and its engine may be fuelled by liquefied natural gas (LNG) or liquefied petroleum gas (LPG). The latter is a gaseous fuel obtained from the distillation of oil.

Generators powered by LNG fuelled engines get their fuel from the natural gas distribution network, whereas LPG fuelled generators are connected to a tank which will have to be periodically refuelled.

What are the benefits of natural gas powered generators?

- They are more respectful of the environment, because the gas causes less emission than other non-renewable fuels (such as coal, diesel or gasoline).

- They are economical, because gas is the most affordable fuel, second only to coal (which is not an option due to its high emission level).

- They are high-efficiency generators in co-generation applications.

- When fuelled by an underground natural gas network, the fuel supply is not conditioned by inclement weather or problems with the communication infrastructure (which do condition diesel generators that need periodic refuelling).

- They are highly compatible and easy-to-use units, given that it is possible to install them in remote locations, using high capacity tanks.

- They are very quiet generators.

Among the disadvantages of this type of generator, one must consider the following:

- Liquefied natural gas (LNG) powered generators are less autonomous than diesel engine ones because it is absolutely necessary to connect them to a distribution network.

- In the case of LNG equipment connected to the network, one has to take into account that any catastrophe or natural disaster can affect the supply system.

- Gas is an exceptionally flammable fuel and entails a bigger fire hazard than diesel.

- The engine and control system are much more demanding, which can result in the product’s final price being higher.

- They require a more punctual and complex maintenance.

Diesel vs Gas Generators: Which One Should You Choose?

Deciding between a diesel or gas-powered generator requires careful consideration of various factors. Each type has its own set of advantages and disadvantages that make them suitable for different applications and environments. Here are the key factors to consider:

1. Application and Usage

- Primary Power Source: If you need a generator for continuous operation, such as in remote locations without a power grid, diesel generators are often preferred due to their robustness and fuel efficiency.

- Emergency Backup: Both diesel and gas generators can serve as reliable backup power sources. However, gas generators, especially those connected to a natural gas line, can provide uninterrupted fuel supply during emergencies without the need for refueling.

2. Environmental Impact

- Emissions: Gas generators produce fewer emissions compared to diesel generators, making them a more environmentally friendly option. This can be a critical factor if you are concerned about meeting stringent environmental regulations or minimizing your carbon footprint.

- Noise Levels: Gas generators are generally quieter than diesel generators, which can be important in residential areas or locations where noise pollution is a concern.

3. Fuel Availability and Cost

- Fuel Costs: Diesel fuel is typically more expensive than natural gas, but it provides higher energy efficiency, which can offset the cost over time.

- Fuel Supply: Gas generators connected to a natural gas line have a continuous fuel supply, whereas diesel generators require regular refueling. However, in areas without natural gas infrastructure, diesel may be the more practical choice.

4. Maintenance and Longevity

- Maintenance Requirements: Diesel generators are known for their durability and lower maintenance needs. Gas generators, while efficient, often require more frequent and complex maintenance due to the nature of the fuel and engine.

- Lifespan: Diesel generators tend to have a longer operational lifespan, making them a more cost-effective option in the long run for high-demand applications.

5. Safety Considerations

- Flammability: Natural gas is highly flammable, posing a greater fire hazard compared to diesel. Diesel fuel, being less volatile, is considered safer to store and handle.

- Reliability: In situations where natural disasters might disrupt gas supply lines, diesel generators offer greater reliability as they can operate independently of external fuel supply networks.

What About Gasoline Generators?

In some markets, especially in North America, “gas-powered generator” often refers to gasoline-fueled engines. While these are common for small portable generators, this article focuses on natural gas and LPG-powered equipment, typically used in industrial and backup applications.

Frequently Asked Questions

1. What is the difference between a diesel and a natural gas generator?

Diesel generators run on diesel fuel and are known for their durability, fuel efficiency, and high performance in demanding environments. Natural gas generators use either piped natural gas (LNG) or liquefied petroleum gas (LPG), offering lower emissions and quieter operation.

2. Which generator is more efficient, diesel or natural gas?

Diesel generators are typically more fuel-efficient and better suited for continuous use or high-load applications. However, natural gas generators may offer better cost efficiency in areas with existing gas infrastructure.

3. Are natural gas generators more environmentally friendly than diesel?

Yes. Natural gas generators produce significantly fewer emissions, including NOx and particulate matter, making them a more environmentally friendly choice compared to diesel generators.

4. Can a natural gas generator run during a power outage?

Yes, especially if it’s connected to a natural gas grid. These generators can provide uninterrupted fuel supply during emergencies without the need for manual refueling—unlike diesel units.

5. What are the maintenance differences between diesel and gas generators?

Diesel generators require less frequent maintenance and are generally easier to service. Gas generators may require more specialized maintenance due to their fuel system and engine complexity.

6. Which type of generator lasts longer?

Diesel generators usually have a longer lifespan thanks to their robust design and lower engine RPMs. They’re ideal for intensive use and long-term reliability.

Conclusion

Choosing the right generator depends on your specific needs and circumstances. At Genesal Energy, we understand that every project is unique. Our experts are here to help you assess your requirements and recommend the best solution tailored to your needs. Whether you prioritize environmental impact, fuel efficiency, or operational reliability, we provide comprehensive guidance to ensure you make an informed decision.

For personalized advice and more information, please contact us at:

consultas@genesal.com +34 900 730 124

Dereating: how Temperature and Elevation Affect Generators

/0 Comments/in Articles, Communication/by genesalIn certain environmental conditions, generators can suffer power losses. Preventing these will allow us to ensure the maximum efficiency of our equipment.

All engines and alternators are capable of offering 100% capacity when they operate in standard or not so demanding environmental conditions, but when they must function in environments with high ambient temperature or at a high elevation or altitude above sea level, their capacities may be reduced.

The engine manufacturers, for instance, usually guarantee a certain performance provided that some values are not exceeded (generally a temperature of 25ºC and 1000 m above sea level). If these values are exceeded, the user has to bear in mind that, very likely, the engine will not perform at its top capacity.

This loss of power in function of temperature and elevation is known as derating, and is something which has to be very much taken into account when it comes to sizing a generator.

Generator dereating factor in conditions of altitude

Just as it happens to us human beings as we climb higher above sea level, the lack of oxygen and the low pressure affect the performance of the generator.

Elevation affects all kinds of engines, but this effect is more prevalent in atmospheric engines, which depend upon atmospheric pressure for the air to reach the cylinders adequately. These losses of power may even occur at elevations below 1000 meters.

In the case of turbo engines, the turbine is capable of countering this air deficit. Therefore, generally, the power derating of this type of engines starts to occur at an elevation of 1000 meters above sea level and its effect is inferior to that affecting atmospheric engines.

The alternator also suffers at a higher elevation, given that with less air it tends to overheat. In general, the majority of manufacturers guarantee that the alternators will not lose power until reaching 1000 meters above sea level. At higher values, the average loss of power is generally of 3% for 500 m of elevation.

Generator performance at high temperatures

Generally, temperature affects generator engines starting at 40ºC. Above this ambient temperature:

- The air is already very hot and its quality is no longer optimal to generate good combustion when mixed with fuel. This generates loss of power.

- The fuel may reach the engine at an excessive temperature, and combustion will not take place in adequate conditions.

- The efficiency of the cooling system will be diminished. As a result, if the radiator is not correctly sized, the generator can stop functioning due to an excessive water temperature.

Generator derating ambient temperature

As far as the alternator is concerned, it is also affected by high temperatures. The majority of manufacturers guarantee the power of their alternators, as long as they operate at an ambient temperature of below 40°C. At higher values, the derating in an alternator is generally of 3% for each additional 5º C.

The importance of having foresight

Given all of the above, when sizing a generator, it is crucial to have a clear understanding of the environmental conditions under which it will operate, i.e.: the inferior and superior limits of ambient temperature and barometric pressure in the setting-up location, as well as the elevation above sea level at which the equipment will be located.

With this clear information provided, we, the engineers, shall be able to foresee and counter the effects of power derating, selecting the most adequate engines and alternators for each equipment.

If your project will be carried out in extraordinary environmental conditions, we at GENESAL ENERGY can advise you and size your generator in such a way that your ideas never lack power.

Risks and Consequences of Using Generator Sets at a Low Load Operation

/in Articles, Communication/by genesalMinimum load for generators

Generator sets are designed to operate close to their rated power, and maintaining them properly is essential to ensure optimal performance. Every generator has a recommended minimum load, typically around 50% of its rated capacity. Operating below the generator minimum load for extended periods can lead to serious issues and reduced lifespan.

Main symptoms of something malfunctioning

One should be concerned when:

- The engine gives off oil mixed with fuel through the exhaust manifold – including the exhaust outlet or the muffler.

- There is oil spillage, dripping of oil of a very dark colour, as if burnt.

- The exhaust gives off a white smoke, more smoke than usual is seen or there is soot coming out of the exhaust outlet.

- The valves and tubing are clogged by dirt (presence of cinder).

The effect of low load on generator performance

“We saw engines working continuously for 24 hours at a tenth of their load and exhaust manifolds with six centimetre holes reduced to one centimetre by the accumulated cinder and oil”, Genesal Energy Technical Director Guillermo Docampo explains.

The effect of low load on a generator includes serious internal damage over time, particularly due to incomplete fuel combustion and oil dilution. These issues directly impact engine health and efficiency.

Negative effects of low load:

- Large accumulation of soot (cinder) in the pistons, in the grooves of the piston rings, in the valves and the turbocharger. If, subsequently, the engine functions at full load the pistons may be blocked by faulty lubrication.

- Low temperatures will result in insufficient combustion of the fuel, which, in turn, will cause the lubricating oil to be diluted and lose its properties because part of the fuel has mixed with the oil.

- Grinding of the cylinder liner. Excessive wear.

- The non-consumed fuel and the lubricating oil will also penetrate the exhaust manifold and will possibly exit through its seals, being very obvious -almost scandalous- because of its burnt aspect and by the stains it causes ((see photo below)).

Important: Do not run an engine generator set without a load for more than 15–20 minutes unless strictly necessary. Prolonged operation without load can lead to internal damage, high oil consumption, and a shortened lifespan of the equipment.

Why does low-load functioning in a repeated and continuous way cause an increase in oil consumption?

In reality, when an engine works at a low load, the ideal working temperature of the engine is not attained. This favours oil flow towards the upper part of the piston, because a correct adjustment within the piston-rings-cylinder assembly was not achieved. This is due to the lack of dilation resulting in an increased consumption of oil; the oil flows more easily between the valve guides and the stems due to a greater clearance because there was no sufficient warming.

How to prevent malfunctions? Is it possible to reduce the risks?

REQUEST THE FULL ARTICLE

Request the full article in the form below if you want more information on how to prevent failures and reduce risks when using generator sets at low load.

Generator load profile and step load explained

/0 Comments/in Communication, Articles/by GestorKnowing the type of loads a generator must power is essential to calculate its required power correctly.

The load profile and the step load —the initial load applied at start-up— are key factors in generator sizing. Power demand is not static; it fluctuates depending on the equipment and conditions, and ignoring these variations can lead to overloads, inefficiencies, or equipment failure.

The power that a generator set manages isn’t an absolute and static value. Its level tends to fluctuate according to certain factors and processes, and it does so differently in each type of unit.

For this reason, calculating the power a generator set needs to function is not a simple operation. Different variables must be taken into account which, if not considered, can cause serious issues in our installation.

For instance, an overload in any of the phases can cause overheating and voltage imbalances. This can cause damage both in the generator set and the equipment connected to it.

Start-up: the first step load

The generator set is going to be limited during its start-up by what is called the first step load, that is: the total transient load that the genset is initially capable of enduring until reaching its stable regime with some transient variations in voltage and frequency.

This is why it’s important to verify the characteristics in the nameplates of the equipment connected to the generator set, and to be aware of the possible transient effects which they may suffer during its start-up processes.

Certain equipment such as pumps or motors with variable drives, for instance, may increase their current temporarily during commissioning.

Likewise, elements such as UPS’s (uninterruptable power supplies) can cause harmonic distortions which must be contemplated in our calculations.

Which parameters affect the dimensioning of loads?

- The first parameter to contemplate is the type of load. As we’ve pointed out, some units experience transient increases in current during start-up. With this in mind, we’ll pay special attention to the following loads:

- Uninterruptable power supplies (UPS). The alternator’s rated power is oversized depending on the installation.

- Big motor loads. They can increase starting power to up to 6 times the power, depending on the type of start-up.

- Lighting loads (with special attention to sodium vapour lighting and metal halides).

- Systems with Variable Frequency Drives (VFD). These can cause an oversizing from 40 to 100%.

- Other loads which are especially sensitive to transients and voltage and frequency variations.

- Another factor we must keep in mind is the type of start-up of the motor in question. This is due to the fact that each type of starter requires a specific starting current, which must be higher than the unit’s rated current. Thus, we find that:

- Electric motors with star-delta starting: its “starting current” will be equal to three times the rated or operating current.

- Direct starting motors: demand 6 times nominal current.

- Starter motors with variable frequency drives: special attention must be payed to its technical sheet as normally the ramp and increase in speed is configurable.

Other important aspects to consider for genset load calculation

To finish carrying out this entire calculation of power with maximum precision, other variables must be kept in mind such as:

- Power factor during start-up.

- Starter power.

- Rated power factor.

- Rated power

- Efficiency

- Number of start-ups

Ultimately, we must be extremely rigorous in this calculation. To avoid any surprises, it’s vital to know the type of load we’re dealing with as well as its behaviour. All, with the objective of the generator set always powering a balanced load, without generating unexpected peaks.

Discover our handy guide to choosing the right power generator

10 Benefits of having a power generator set

/0 Comments/in Communication, Articles/by GestorIn a world increasingly dependent upon energy, technology and data, it is a priority to have a reliable and sustainable supply of electricity. This is precisely what generator sets offer us.

The importance of electric generators

The importance of generators lies in their ability to provide continuous power during outages and support critical infrastructure. In times of natural disasters or unexpected power failures, generators ensure that hospitals, data centers, and emergency services remain operational, safeguarding lives and essential data. Moreover, they enable businesses to maintain productivity and prevent financial losses, highlighting their crucial role in modern society.

However, the virtues of these devices go beyond what meets the eye and it is worth knowing them. We compiled a list of 10 fundamental benefits so that none of them is left out:

What are the main advantatges of having a generator set?

1. Uninterrupted Power: The Importance of Ensuring Continuity

Electricity supply no matter what. Generator sets are meant for you to always have electricity whatever happens. This means that problems with the electrical network will no longer be critical for you, given that you will be constantly backed up by an autonomous generation solution which is 100% effective.

2. Say Goodbye to Downtime: Boosting Productivity

Farewell to losses: relying on the backup of a generator set in your business allows you to forget about time and productivity losses supposed by power blackouts.

3. Empowering Autonomy: Expanding Possibilities

More autonomy, more possibilities: when using an energy distribution solution such as a genset you are no longer dependent on the limitations imposed by the infrastructure of the electrical network. This means more peace of mind and, most of all, more freedom when it comes to conceiving your business projects and letting them fly.

4. Mobile Power Solutions: Enhancing Flexibility

It allows you more mobility: generator sets allow you to have a power supply in areas lacking an electrical network. Therefore, they eliminate obstacles when it comes to carrying out projects and they contribute to the development of remote or disadvantaged areas.

5. Tailored to Your Needs: Customized Designs

Your project is in charge: at present, the design of gensets is tailored to the clients’ needs and the features of their projects. According to your requirements, you will be able to choose: between engines using different fuels, between stationary or mobile generators, between hybrid and marine generators, as well as between different profiles of power delivery and of use.

6. Adding an Extra Layer of Protection: Ensuring Security

An additional security layer: the consequences of a power outage go beyond the mere issue of productivity. A sudden “blackout” can cause severe damage to our devices and machinery and this is something that can be avoided if we have the backup provided by an emergency genset.

7. Sustainable Energy: Reducing Environmental Impact

It contributes to sustainability: as opposed to the great impact left by the emissions produced by thermal power stations, generator sets offer a model of energy production which increasingly allows one to leave the least possible environmental footprint. The present-day trend is represented by generators using fuels with low CO2 emissions, like natural gas or liquefied petroleum gas (LPG). Moreover, these are low noise devices, producing no sound pollution.

8. Long-Term Value: Making a Sound Investment

It is an investment which pays off: A generator set will give you an extremely valuable service and will continue to do so for a long time. Most certainly, with appropriate use and maintenance, you will have a safe, long-term investment.

9. Streamlined Energy Production: Enhancing Efficiency

More efficient energy production: statistics show that electricity losses in the Spanish network of transport and distribution amount to 8% of all available production. Using distribution solutions such as gensets, one manages to reduce such losses. Moreover, we contribute to avoiding overloads in the network during the peak hours.

10. Cutting Costs: Maximizing Savings

You save in consumption: gensets allow you to reduce costs, by helping you manage the electricity demand in a more economical way. For example, you can use them as a backup during peak hours, in order to avoid excessive consumption. According to calculations, you can save up to 40% in this time slot.

In short, a generator set brings you peace of mind, opens up a large spectrum of business opportunities and all this in an effective and sustainable way.

Do you think it could be an interesting solution for you as well?

At Genesal Energy we have a wide experience in the design of personalized generator sets and we’re here to help you turn your project into reality.

Configure your customized

generator set

Contact

Do you need a generator set?

Fill in the form with your information if you want one of our generator sets or if you have any questions. We will prepare a quotation for you based on your requirements.

Customer Service Telephone/Fax:

+34 900 730 124Customer service team Email

consultas@genesal.comGENESAL ENERGY

INTERNATIONAL

We operate in over 40 countries worldwide.

EUROPE | AFRICA | LATIN AMERICA | MIDDLE EAST

R&D+i

GENERATOR SETS

- Diesel Generator Sets

- Gas Generator Sets

- Hybrid Generator Sets

- Stage V Generator Sets

- REQUEST A QUOTE

CERTIFICATIONS

COMUNICATION

Parroquia de Rois, b28

Polígono Industrial de Bergondo 15165

Bergondo, A Coruña

consultas@genesal.com

Officially registered as Manufacturer with references:

RII_PYA: 7848

RII_ENV: ENV/2023/000004191

RII_AEE: 7087

Members of