Emergency power for Moroccan Chemical Plant: optimal performance in the most extreme climates

/in Applications, Oil&Gas Morocco/by GestorElevated areas, high or low temperatures, all create hostile environments for generator sets as they directly impact their operation and essential functions such as startup capability and speed.

That’s why when a client asks us for generator sets to operate in locations with especially adverse climatic conditions, at Genesal Energy we analyze each detail of the territory before designing a generator set which without a doubt calls for a set of characteristics which are more special than usual.

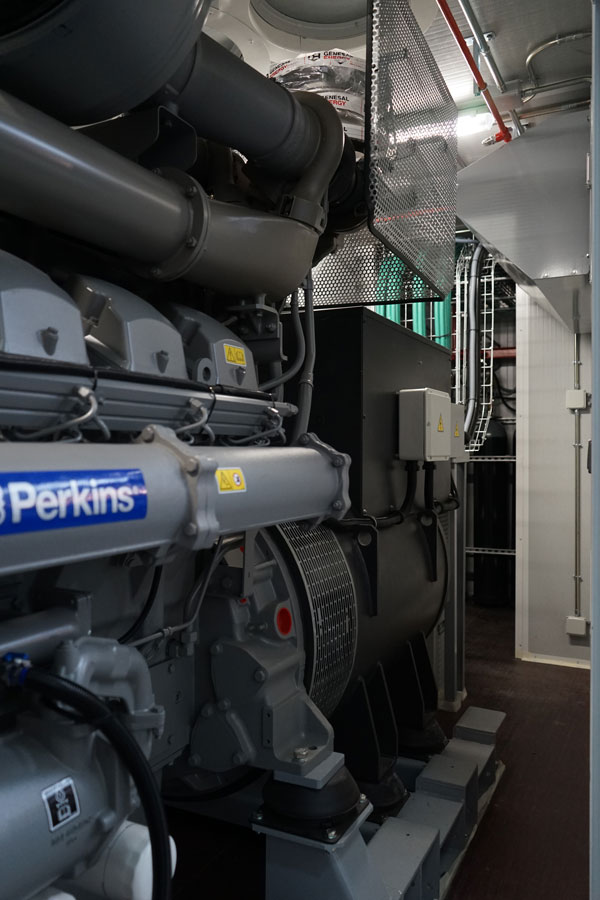

An example of this is a project we carried out in Morocco, for which our engineering team designe dan emergency generator set for a chemical plant in a desert with extremely high temperatures.

For this project, aspects such as the sand, a natural adversary which is hard for this type of equipment to beat, were taken into account. The generator set had to operate in a desert area, with a great amount of sand and suspended dust, as well as extreme temperatures, and so it was fit with dust filters in the air inlet and alternator, which was IP45. Furthermore, a system was designed to pressurize the container, in turn avoiding the entrance of dust. A fuel tank of great autonomy was also installed.

A record time frame

In summary, the generator set was designed to guarantee power supply for the facility’s auxiliary and essential services in the face of a mains failure. Apart from being a bespoke generator set, the whole process was accelerated in order to comply with the tight deadline. This was a great challenge for Genesal Energy as the usual time allowed for development and production for this type of projects was cut in half.

Our experience in the manufacture of gensets for high temperatures has made us a reference brand in countries such as Chile, where we’ve supplied high capacity emergency power in areas as inhospitable as the Atacama desert.

Features

- 20´DV container with C5 coating.

- Inlet dust filters for cooling air and alternator.

- Air conditioned control room.

- Mains synchronization control panel.

- Earthing switch.

- Independent battery and battery charger for control.

- Integrated automatic transfer switch.

- IP45 alternator with special treatment prepared for aggresive environments.

- Double PT100 sensors in alternator windings.

- PT100 sensor in alternator bearing.

- 2000l fuel tank in dedicated room with redundant fans to guarantee adequate room cooling.

- Motorized louvers.

We’ve supplied emergency power to an offshore platform in the Gulf of Mexico

/in Oil&Gas, Applications Mexico/by GestorWe’ve designed a generator set for an offshore platform in the Gulf of Mexico.

It’s a special solution for a special location, as this type of marine platform contains specific loads (pumps, compressors, fans…) which, if ever a failure of the mains supplies or any other incident were to occur, must continue operating to guarantee power supply to the installation at all times.

How does it work?

- In automatic mode, the genset begins its start-up sequence either due to a failure of both of the installation’s mains supplies or at the operator’s will. In the latter case, through a remote contact sent from the client’s DCS. When the genset is ready for the load, the loading sequence begins automatically to feed the installation’s essential loads.When mains supply is reestablished, a non-zero transfer between the mains and the genset is carried out, and the genset stops automatically.

- In manual mode, the client can manage the whole system through the control panel’s touch-screen. From there, its possible to locally start up and stop the genset and manage its breakers, as well as those of the mains and coupling of the semi- busbars.

Why is it a customised solution?

Because we design completely tailor-made solutions, having listened to the client’s needs and establishing how we can turn what they need into reality. At Genesal Energy we design, for example, soundproof gensets which are then installed in a container with elements which have been thought-out and designed to comply with our clients’ concrete needs: from fire-detection systems, to air conditioning, motorized louvers, fans, etc.

In the case of the offshore platform, the genset was designed made-to-measure according to the electrical requirements of the installation, while also having adapted to the operational logic requested by the client, for which a PLC was installed to control the genset and the system.

Features

- Control and power cabinets integrated in the same soundproof container, in a room separate from the engine and alternator.

- Stainless steel cabinets.

- Air conditioning system in the control room.

- Extractor fans to control the temperature in the engine room.

- Motorized louvers on the air inlet and outlet.

- Engine cooling liquid recirculation and heating system to provide the correct temperature for genset start up.

- C5-M treatment on the outer container, according to ISO 12944 norms.

- Container’s external louvers in stainless steel.

- External exhaust silencer with spark arrestor in stainless steel, and with T output and drain.

- Alternator with Total Plus marine impregnation – Total Plus.

- CO2 fire detection and extinction system.

- Air inlet and outlet silencers to reduce sound level to 85 dB.

- Generator differential protection with relay.

- Alternator winding temperature control through PT-100 sensors.

- Neutral earthing resistance through motorized breaker.

- Alternator diodes failure detection module.

- Touch-screen on the control panel to manage and monitor the system.

We are involved in the extension of the Los Azufres plant in Mexico, which obtains renewable energy from the centre of the earth.

/in Applications, Oil&Gas Mexico/by genesalThe genset supplied by Genesal Energy is ready to power the critical loads at2,856 M above sea level, where the plant is situated.

Geotherm is a renewable energy source which is generated by the heat expanding from the core of the earth. Currently, Mexico is one of the most advanced countries in this field, and in Los Azufres the country’s second largest reserve also one of the biggest in the world is found (the largest in Mexico being in the state of Baja California).

The Los Azufres power plant is located in the state of Michoacan, 250 KM from the capital Mexico City. Due to the potential of this energy source, the Federal Commission for Electricity has driven the construction of Los Azufres III-Phase 2 expansion, with a net capacity guarantee of 25MW. This will be focused on supplying power to the Michoacan cities of Hidalgo and Zinapecauro. The objective is to ensure a stable and renewable supply for the ever-increasing energy demands in the region.

Genesal Energy has supplied emergency back up power for the plant, a made to measure generator set, very different to standard gensets, in that it can operate at almost 3000M above sea level.

The generator set, was the result of an exhaustive study detailing all the technical requirements of the project. Various aspects were analysed such as the conditions the genset would be working in, as well as calculating the loads it would support and the load steps in order to determine the most adequate engine and alternator.

The role of the new generator set in the Los Azufres Geothermal Plant is to supply power to the critical (essential) loads in the case of a mains grid power failure, with the objective of bringing the power plant to a safe shutdown and not a sudden stop. This is achieved using an Automatic Transfer System (ATS) to switch the power from the mains to the genset.

Some other interesting facts about this Project

- The control panel was designed to a very specific specification, which was supplied by the client’s engineers – requiring a control cabinet with a PLC (Programmable Logic Controller) and a Siemens Siplus touchscreen.

- The control panel and the entire genset installation has been prepared to work in an environment with a high concentration of H2S (sulphuric acid – a gas which is heavier than air, inflammable and colourless). To protect against H2S and for easy maintenance all the PLC cards are covered with an acrylic based plastic. Additionally, the connectors on the cards and where they connect are gold plated to withstand a permanent concentration of 3mmm of H2S gas.

- It comes with a Modbus tcp/ip card and a fibre optic converter via a manageable switch with two fibre optic ports to create a fibre optic ring and guarantee continued communications.

- As well as communication, the most important signals are sent wired. This ensures all the genset information is stored in the Scada system in the DCS of the geothermal plant, and total control via SCADA.

Contact

Do you need a generator set?

Fill in the form with your information if you want one of our generator sets or if you have any questions. We will prepare a quotation for you based on your requirements.

Customer Service Telephone/Fax:

+34 900 730 124Customer service team Email

consultas@genesal.comGENESAL ENERGY

INTERNATIONAL

We operate in over 40 countries worldwide.

EUROPE | AFRICA | LATIN AMERICA | MIDDLE EAST

R&D+i

GENERATOR SETS

- Diesel Generator Sets

- Gas Generator Sets

- Hybrid Generator Sets

- Stage V Generator Sets

- REQUEST A QUOTE

CERTIFICATIONS

COMUNICATION

Parroquia de Rois, b28

Polígono Industrial de Bergondo 15165

Bergondo, A Coruña

consultas@genesal.com

Officially registered as Manufacturer with references:

RII_PYA: 7848

RII_ENV: ENV/2023/000004191

RII_AEE: 7087

Members of