Genesal Energy, delivering energy in the most extreme climates

Securing energy supply in climates with extreme conditions, be it cold, heat or humidity, is a challenge that Genesal Energy is familiar with. In this case, the challenge of the project was to provide a solution in the extremely cold environment of Finland.

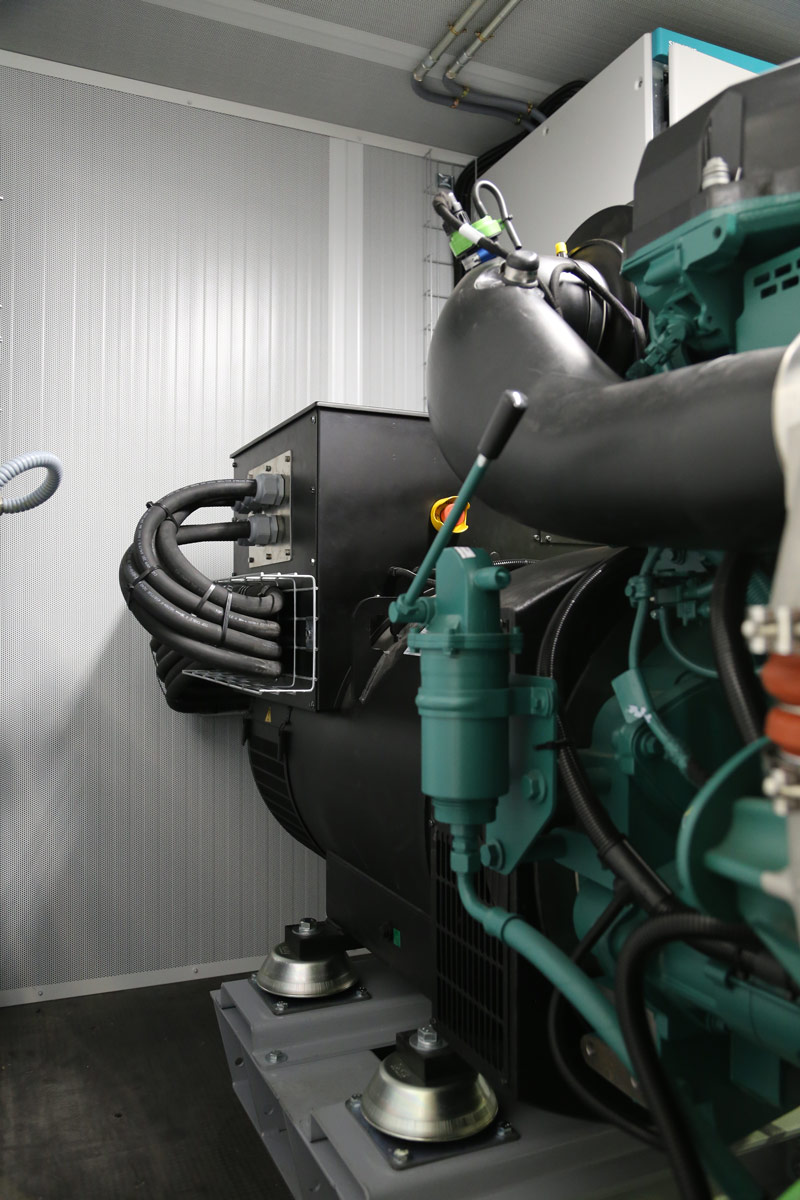

Faced with the need for reliable equipment to ensure the uninterrupted operation of the installation in the event of a mains power failure, we designed a generator set fully integrated into a 20 feet HC container, adapted to the demands of the environment and prepared to guarantee the continuity of the power supply. In addition, it had to be able to operate in low temperature conditions, be compact for easy transport and have the greatest possible autonomy. A technical challenge that we solved with a customised design.

Another key aspect of the design was the optimisation of space to increase the autonomy of the equipment.

To guarantee the correct operation of the unit in these climatic conditions, we incorporated a system of motorised grilles between the unit and the air outlet. These louvres allow air inlets and outlets to be closed, while the opening of an intermediate louvre creates a flow of hot air inside the container until the right temperature is reached. It is equipped with a heating recirculation pump to guarantee start-up in extreme conditions. At the same time, customised soundproofing ensures that the noise level is extremely low.

Another key aspect of the design was the optimisation of space to increase the autonomy of the equipment, so we designed a customised fuel tank with a capacity of 2,000 litres, with a double steel wall and strategically located at the entrance of the container. Its rectangular format allowed us to make better use of space without compromising accessibility.

Our Engineering Solution

Our team designed a solution totally adapted to the customer’s needs and focused on solving two problems: on the one hand, withstanding low temperatures, and on the other hand, increasing the autonomy of the unit as much as possible.

Features

- Large capacity tank. 2.000 litres double walled (Steel-steel).

- Recirculating heating pump.

- Integrated silencer in container, GSI 490 (-30 dB).

- 630 A, 3-pole, LSI circuit breaker.

- Battery protection box with ventilation.