The future of generator sets: More sustainable and connected

In an increasingly complex energy landscape, where electrification, renewable energies and the need for continuous power supply coexist even in the event of grid failures, generator sets play a decisive role. Their evolution in terms of sustainability, efficiency and connectivity is redefining their presence in critical sectors and in environments where generating electricity in an environmentally responsible way has become an essential requirement. This article analyses how the sustainable generator set is evolving, its role in the energy transition and the technologies that will shape its future.

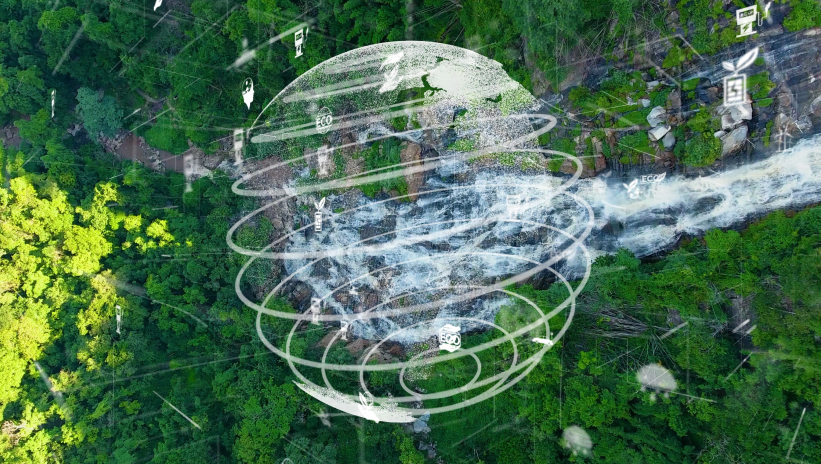

The role of generator sets in the energy transition

The transition towards clean energy has driven a profound change in the way energy is produced. As the penetration of renewable energy increases within the energy mix, so too does the need for backup systems capable of guaranteeing continuous power when environmental conditions prevent renewable sources from fully meeting demand.

The future of generators lies in further promoting hybrid solutions, alternative fuels and technologies that make better use of renewable energy.

In this context, the generator set remains a strategic energy source. Its role is no longer limited to acting as emergency equipment: today it is integrated as part of the energy ecosystem of industries, hospitals, data centres and critical infrastructures, providing operational flexibility and security. For companies and public administrations, ensuring energy supply in the event of interruptions or demand peaks is essential, and generators are becoming a key tool in this new hybrid and dynamic model.

How to reduce environmental impact in power generation

Sustainability has become a central pillar in the design and manufacture of equipment intended to generate electricity. The need to reduce the greenhouse effect and to develop increasingly environmentally friendly equipment has led to new approaches aimed at creating generator sets adapted to the environmental requirements of the future.

This progress involves action on several fronts: improving engine efficiency, optimising combustion systems, reducing energy losses and using materials with a lower environmental impact. In addition, eco-design principles and the identification of environmental aspects at each stage of the generator’s life cycle help minimise its environmental footprint, from initial design through to on-site operation.

Increasingly stringent emissions regulations are also accelerating the development of cleaner generators, capable of operating with lower consumption and reduced pollutant emissions. As a result, manufacturers are investing in technologies that reduce emissions without compromising the operational reliability that characterises these systems, while maintaining optimal performance.

Use of alternative fuels and renewable energies

The path towards a sustainable generator necessarily involves fuel diversification. The introduction of HVO (hydrotreated vegetable oil), advanced biofuels or even blends with green hydrogen opens up a range of solutions to progressively replace traditional fossil-based fuels.

Efficiency is one of the main indicators of technological progress in generator sets.

Renewable fuels allow generators to operate with a significantly lower carbon footprint and offer additional advantages: they require no major modifications to many modern diesel engines and maintain the operational stability needed for critical environments. These alternatives are complemented by the growing drive to integrate generator sets into hybrid systems based on renewable energy.

Ongoing R&D in this field is enabling generators to operate as part of a flexible energy system in which sustainable fuels, energy storage, power electronics and renewable energy sources coexist to optimise every kilowatt consumed.

Integration of generator sets with solar panels and wind energy

Infrastructures that combine generators with solar panels or wind farms are no longer a trend, but a rapidly expanding reality. The combination of generators and clean energy sources makes it possible to reduce fuel consumption, extend autonomy and lower overall system emissions.

In off-grid applications, such as remote areas not connected to the electricity grid, hybridisation is essential to produce energy efficiently. Solar panels provide daytime generation, wind energy complements supply at variable times, and the generator acts as a backup when weather conditions do not allow demand to be fully met. This model improves overall system performance and significantly reduces dependence on fuel.

The result is a sustainable power generator capable of operating in complex scenarios, offering greater autonomy and optimised control of available resources.

Technological advances to improve efficiency and reduce emissions

Efficiency is one of the main indicators of technological progress in generator sets. The development of more advanced engines, high-pressure injection systems, optimised turbochargers and exhaust after-treatment systems has enabled modern generators to consume less fuel and emit fewer pollutants to meet the same energy requirements as previous generations.

The transition towards clean energy has driven a profound change in the way energy is produced.

Improvements are not limited to the engine itself: electronics play a decisive role in load management, start-up optimisation, avoidance of unnecessary consumption and adjustment of operation to real demand. In parallel, energy storage solutions make it possible to combine batteries and generators to further reduce consumption when demand is low.

Continuous innovation in these areas helps consolidate the sustainable generator set as a more efficient solution, ready to meet future environmental standards.

Connectivity and intelligent monitoring in power generators

Connectivity has transformed the way data from modern generators is managed and interpreted. Remote monitoring systems allow real-time supervision of operating parameters, alarms, consumption, emissions and load trends. Thanks to this connectivity, equipment benefits from more effective predictive maintenance, higher availability and lower operating costs.

Digitalisation turns the generator into an active element within the energy ecosystem, capable of communicating with other equipment, integrating into management platforms and supporting data-driven technical decisions. For industries that require continuous power, this intelligence adds security, reliability and efficiency.

Trends and the future of generator sets in a sustainable world

The future of generators lies in further promoting hybrid solutions, alternative fuels and technologies that make better use of renewable energy. The trend is clear: to develop equipment that reduces environmental impact without sacrificing the reliability that has always defined the sector.

The combination of technology, sustainability and connectivity is shaping a new standard in which the generator becomes a flexible, optimised element capable of integrating with clean energy sources to deliver efficient, stable power supply aligned with the demands of a more sustainable world. In this scenario, companies that invest in innovation and environmentally responsible approaches will lead the transformation towards a safer and more resilient energy system.