Emergency power solution for the Álvaro Cunqueiro Hospital

Localization

Situated in the city of Vigo, north-west of Spain, the new hospital Álvaro Cunqueiro covers an area of 280,000 m², has beds for 1,465 patients and will provide healthcare servides to a population of 600,000 people.

Requirements

The customers asked GENESAL ENERGY for a full back-up energy solution in case of a mains failure, to cover a total of 11.2 MW (14,000 kVA) with automatic start system and conection to the SCADA room. The solution needs also to comply with high noise attenuation standars to not affect the normal functioning of the hospital when running.

Solution

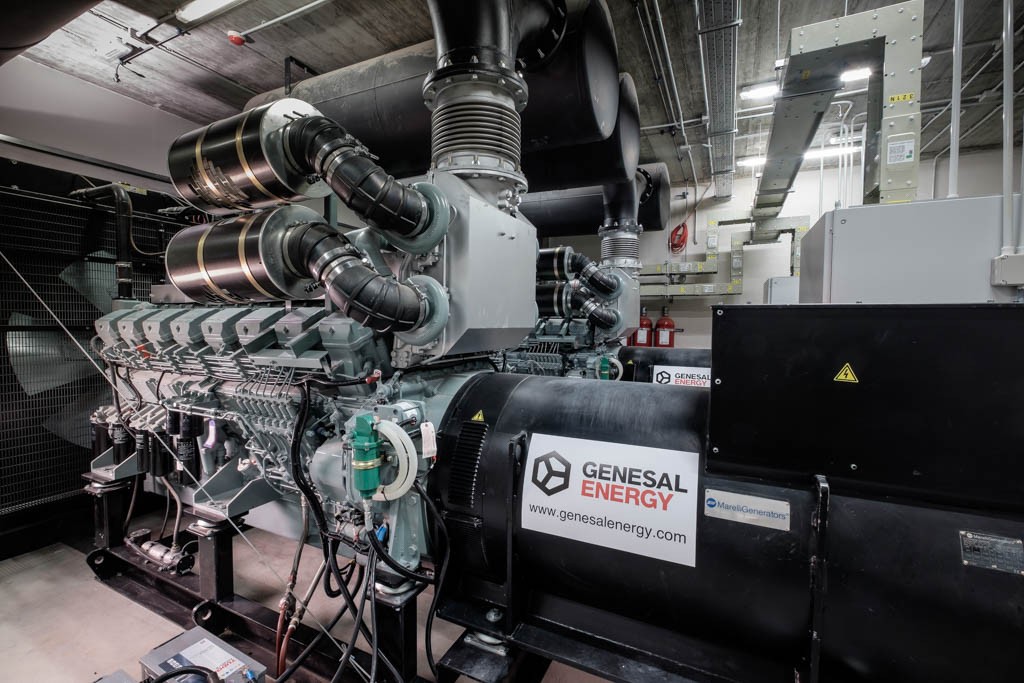

Genesal Energy designed, manufactured and commissioned eight gensets to provide the hospital with the 11.2 MW needed:

- Six GEN1875H (1,875 kVA/1,500 kW).

- Two GEN1375H (1,375 kVA/1,100 kW).

With the following special features:

- Automatic start upon mains failure with 3-phase monitoring of mains.

- Full control system and automatic transfer switchboards.

- Modbus communication between generator and SCADA room.

- Maximum sound attenuation through -40dB silent exhaust system and sound attenuator.

- Automatic fuel transfer system between each individual fuel tank and the main fuel tank of the facilities.

Benefits

GENESAL ENERGY provided the customer with an fully automatic and an over-the-top reliable solution, designed under a strict specification sheet, both for safety and comfort.