Emergency Energy for the Chilca Combined Cycle Power Plant

Combined Cycle Plant in Chilca (Peru)

Emergency diésel power generator to be installed in a Combined Cycle Plant in Chilca, Lima province, Peru. The plant has a General Electric gas turbine and a Siemens steam turbine , capable of generating a net 110 MWe.

Requirements

- Space limitations.

- Internal division between 3 rooms: generator room, control room and tank room. The control room must be climate-controlled.

- 6 hours of independent operation at 100% load.

- Corrosive atmosphere with high content of suspended dust.

- Maximum noise level 85 dBA at a distance of 1 metre.

- Fire detection and extinguishing system.

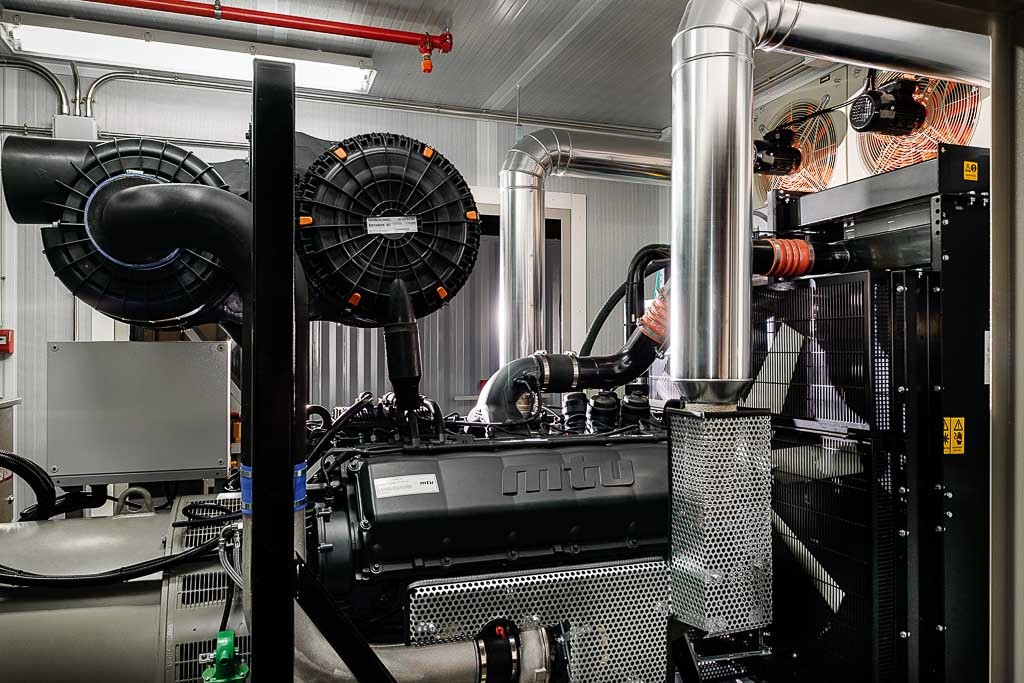

Unit design

Based on a study of the loads to be supplied, the selected power unit had a rating of 680/750 kVA, 60 Hz, 480 V. To meet the requested specifications, GENESAL ENERGY chose the following solutions:

- To overcome the space limitations, the unit was assembled in a 30’HC container designed especially for the project.

- The unit as required was divided in to 3 rooms:

- Generator room: Containing the power generator along with the batteries.

- Control room: The control panel and generator power panel are installed in this room. The wiring connections are located at the bottom of the generator.

- Tank room: A custom-made, approved, 1500 litre double-walled parallel piped-shaped tank was installed, guaranteeing 6 hours of independent operation at full load.

- Because the atmosphere where the generator would be operating is highly corrosive (marine atmosphere), it was painted in accordance with ISO 12944, following a C5M diagram, which consists of type SA 2 ½ shot blasting in accordance with ISO 8501, one initial 80 µm coat of zinc-rich paint, two 100 µm coats of epoxy paint and a final, 100 µm coat of polyurethane paint (RAL 7032), giving a total dry film thickness of 380 µm.

- The atmosphere where the generator is located has a high content of suspended dust. Therefore, powered grilles were installed on the generator’s air intake and outlet. The slats open when the generator is operating and close automatically when the generator shuts down.

- To meet the noise requirements, the generator was attenuated with acoustic panels consisting of rock wool and perforated plates, and was equipped with noise reducing filters on the air intake and outlet. The exhaust soundproofing was installed inside the container to avoid complications during the on-site installation.

- The fire extinguishing system includes a detection component consisting of a smoke detector system in all 3 rooms aswell as an extinguishing system that uses water mist in the engine room and tank room, and CO2 in the control room.

- The control panel was designed to meet the specific requirements of the project engineering team.

- Redundant programmable automaton.

- Fibre optic communication with the redundant DCS by modbus TCP/IP.

- 4” touchscreen.

- Protection relay meeting the following ANSI-based electrical protection requirements: 50, 51, 51N, 59N, 59, 27, 81m, 81M, 46, 49, 25, 78, 32, 40.

- Protection relay meeting the following ANSI-based electrical protection requirements: 87G, 24.

- Synchronizer between generator and networks.

Prime Prime: 680 kVA

Standby Prime: 750 kVA

Voltage: 480 / 277 V

Frequency: 60 HZ

Engine: MTU

Alternator: Leroy Somer