Deportivo Alaves stadium illuminated by Genesal Energy

/in Applications, Other applications Spain/by GestorEnergy with remote control modules for the French bank Credit Agricole, a leading European high street bank.

/in Applications, Other applications Spain/by Gestor

Leading European banking institution Credit Agricole with their headquarters in France and a strong presence in Spain has put their trust in Genesal Energy to carry out a project from the design stages to execution in order to supply emergency power in one of their key branches in the famous Paseo de la Castellan in Madrid.

Not only are Credit Agricole a key credit supplier in France, they are also one of Europe’s biggest banks, and manage more active assets than any other bank on the continent. They are also Europe’s biggest insurer and financer of large projects.

The project undertaken by Genesal for CA consisted in supplying two emergency gensets, each with a rating of 630kVA. The gensets were to form part of the overall electrical set up within the building, and have been set up to start up automatically should the mains electricity supply cease to operate, and therefore guarantee the ongoing operational status if the bank.

In this particular case, as the end user is a major international bank, it is essential to have a back-up power system as the knock-on effect to the whole business in the event of a power loss can cause complex issues to arise. This particular site needs to be powered 24 hours a day, there is no margin for error.

Any time, any place

The gensets supplied by Genesal Energy have been designed to incorporate a remote-control communication module, permitting start up and switch-off of the gensets online at any time from any location on the planet.

This type of communication system also allows for preventative maintenance to be carried out. Using a communication card, Genesal’s technical service department can visualise all the different parameters of the gensets. This permits instant recognition of potential alarms or anomalies that may occur in the future. This type of real time instant detection means Genesal Energy can ensure the gensets never reach a critical point which may affect their ability to function correctly.

Additionally, the gensets have been soundproofed so that they could be installed on the rooftop, and as such minimising the acoustic contamination in the vicinity.

TECHNICAL DATA

- Prime Power: 570Kva

- Emergency Power Rating: 630Kva

- Voltage: 400/230V

- Frequency: 50Hz

- RPM: 1,500rpm

- Dimensions: 5000mm x 1886mm s 2356mm

- Weight: 5,680 Kg

- Modbus TCP/IP communication protocol

- Electronically adjusted engine

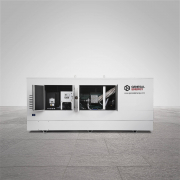

GEN80FC – Extra Soundproof Genset

/in Applications, Communication, News, Other applications Spain/by Gestor

CHARACTERISTICS

Extra Soundproofed Genset

Power: 80 kVA COP, 100 kVA PRP & 110 kVA STANDBY

Project: Data Processing Centre, Abanca.

Location: Paseo de Recoletos – Madrid

SPECIFICATIONS

- Diésel genset with 65dB(A) sound measurement at 1M distance.

- Integrated silencers on the air intake and the exhaust.

- Double thickness sound absorbing rock wool as standard issue for the entire enclosure including the base.

- Electronic Engine Control Unit installed, which guarantees a more stable performance.

- Alternator provides voltage stability of ±0,5%.

- Card for Modbus set up.

- Sub base fuel tank for a 20 hour plus autonomy at COP rating.

- Integrated fuel level sensors for automatic fuel transfer management.

- Extra addition of silent blocks to add to those mounted between the bench frame and the engine-alternator mono block, in order to eliminate any residual vibrations once installed in the building interior.

CASE STUDY

In the engineering side we had to consider various needs.

On the one hand, and due to the unusual location of the genset inside a building in the middle of Madrid, it was necessary to ensure a genset design solution which met with the local regulations pertaining to legally permitted acoustic levels. Genesal’s engineering department proposed the manufacture of a specially built genset to comply with Madrid’s legally permitted acoustic levels. This involved several key design aspects such as extra thick walls on the genset enclosure, silencers integrated in to the air intake and exhaust systems, as well as sound proofing the base frame. This led to the development of a one piece completely enclosed mono block. Additionally Genesal went a step further and researching the need for added silent block anti-vibration parts to the standard number used in manufacture, to eliminate residual vibrations that may increase the noise output.

This was not the only consideration. Genesal’s engineers correctly assumed that the complexity of the location required a unique fuel transfer and control system for the loads to be handled by the genset. This required a fuel tank to be situated in the basement of the building, and a controlled transfer method to be installed. A special alternator was added to guarantee very high stability at different frequencies regardless of the genset load levels, with an added electronic engine speed control unit (ECU) to ensure continuous stability.

Contact

Do you need a generator set?

Fill in the form with your information if you want one of our generator sets or if you have any questions. We will prepare a quotation for you. We will prepare a quotation for you based on you requirements.

Customer Service Telephone/Fax:

+34 900 730 124Customer service team Email

consultas@genesal.comGENESAL ENERGY

INTERNATIONAL

We operate in over 30 countries worldwide.

EUROPE | AFRICA | LATIN AMERICA | MIDDLE EAST

R&D+i

GENERATOR SETS

- Diesel Generator Sets

- Gas Generator Sets

- Hybrid Generator Sets

- Stage V Generator Sets

- REQUEST A QUOTE

CERTIFICATIONS

COMUNICATION

Parroquia de Rois, b28

Polígono Industrial de Bergondo 15165

Bergondo, A Coruña

consultas@genesal.com

EEE Producer Registration Number EE 7087

Members of